Four years ago, we wrote about PragmatIC’s ultrathin and flexible plastic electronics circuit, with news that an ultra-cheap ARM Cortex M0 MCU made of plastic materials was coming soon.

In this case, “soon” means about four years, but Arm has now finally announced PlasticArm, an ultra-minimalist, fully functional Cortex-M0-based SoC, with 128 bytes of RAM and 456 bytes of ROM that, with 18,000 gates, is twelve times more complex than previous state-of-the-art flexible electronics.

PlasticArm specifications are similar to a standard Cortex-M0+ core with some notable exceptions:

- Cortex-M core in PlasticARM

- ARMv6-M architecture

- ISA – 16-bit Thunb and subset of 32-bit Thumb

- 32-bit data access and address width

- 86 instructions

- 2-stage pipeline

- Architectural register file mapped to RAM external to the CPU (instead of inside the CPU)

- Runs code from other Cortex-M CPUs

- 0.8-μm process

There are two main advantages of PlasticArm. First, It’s flexible and integrated into paper, plastic, or metal foil substrates. It’s also much cheaper to mass-produce with Arm saying it would cost less than 1/10th the cost of silicon in 2017. That means ultra-low-cost PlasticArm microcontrollers would become commercially viable in new use cases include flexible smart sensors, smart labels, and intelligent packaging. Arm especially sees great potential in the healthcare sector and for the reduction of food waste.

The manufacturing process and other details are explained in a white paper in Nature magazine:

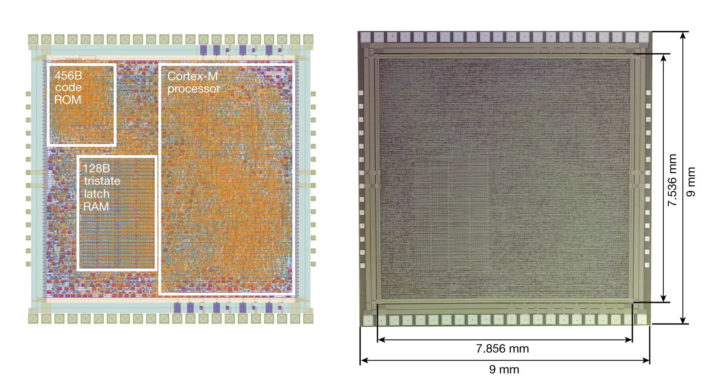

PlasticARM is fabricated using a commercial ‘fab-in-a-box’ manufacturing line, FlexLogIC, and its die micrograph is shown in Fig. 1d. The process uses an n-type metal-oxide TFT technology based on indium−gallium−zinc oxide (IGZO) and generates the FlexIC design on a 200-mm-diameter polyimide wafer. The IGZO TFT circuits are made using conventional semiconductor processing equipment adapted and configured to produce devices on a flexible (polyimide) substrate with a thickness of less than 30 μm. They have a channel length of 0.8 μm, and a minimum supply voltage of 3 V.

Three test programs have been run successfully on the microcontroller tot test all features and instructions. Each program was pre-programmed/hardwired into the ROM before fabrication, and compiled with the standard armcc compiler using the CPU flag set to ‘cortex-m0plus’. That means at this stage the ROM is really “read-only memory”, and programmable once, but eventually, programmable ROM may become available. It’s also really slow at this time, as the paper reads PlasticARM is fully functional up to 29 kHz at 3V and 40 kHz at 4.5V.

We probably still have a few years before us because flexible Arm microcontrollers become available as more research is needed to lower power consumption and improve the solution as a whole.

Via Twitter.

Jean-Luc started CNX Software in 2010 as a part-time endeavor, before quitting his job as a software engineering manager, and starting to write daily news, and reviews full time later in 2011.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress

What’s the use case here? There’s already quite a few Cortex M0+ MCU’s in tiny packages (sub 3x3mm), and there aren’t many places where you can’t stick them in where you could stick this in.

Like it says in the article its flexible so can be integrated in all kinds of substrates and its cheap so it can be used in disposable products. Would be a waste to put real silicon in disposables 😉

More plastic, the worlds air, water and seas, need more plastic.

To get data on your body, or a flexing joint cable of whatever material (think “aging infra”), both could be embedded with tiny sensors, or even plopped in during 3D printing. [ Heck, even body parts are likely to become 3D printed, with sensors already inside, no injection necessary. Imagine a bone or a damaged muscle, tendon, ligament ]. Those sensors would not have much power, by design, or run on body heat or other electromagnetic radiation. Processing anything would take up too much real estate…so that minimalist processing would need to be external, and perhaps, put up with bending, beating, flexing, pulling, torsion.

The target cost is 1/10 of silicon versions. What WON’T they attempt to make this the use case for?

What about plastic FPGA? It’d be cool to 3-D print an FPGA at home, even if its slow as molasses.