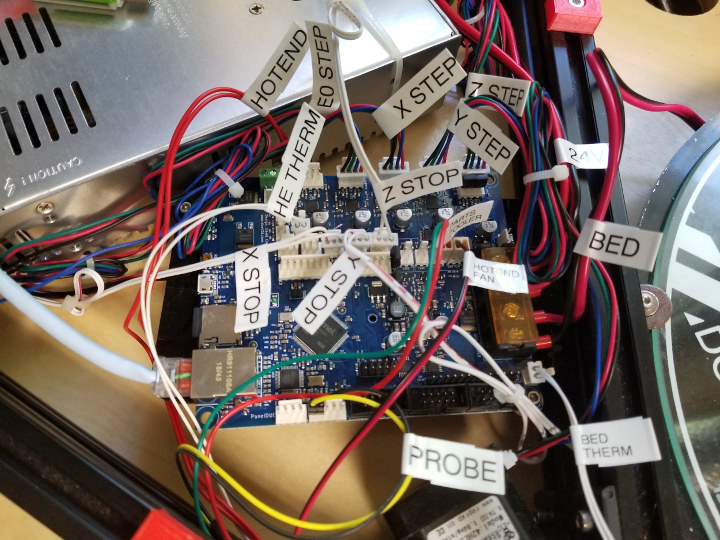

Quite a while ago I reviewed the HE3D K280 delta 3D printer. Up until now, I did no mods other than the ones that I completed during the initial build. I have been very happy with it with the exception of the noise caused by inexpensive drivers and the salmon skin due to the drivers as well. The K280 prints big and pretty accurate at modest speeds. Today I am outlining how I upgraded to a Duet 2 Maestro mainboard. With this upgrade, I am jumping from an 8-bit board with generic drivers to a 32-bit board with TMC2224 drivers. The upgrade was quite painless and straightforward but not without a few hiccups. The Maestro is Duet’s entry-level board for about $130. I attempted the Bigtreetech SKR 1.3 with TMC2130’s but the firmware wasn’t quite there yet. I opened an issue on Marlin’s GitHub page which explains the issue in […]

BQ Ciclop is an Open Source Hardware 3D Scanner Kit

I’ve already written about 3D scanners, and at the time mentioned the price range varied a lots from just around $100 fo entry-level models to over several thousands dollars for professional solutions. This morning I saw a tweet for one of the cheap model by HE3D, where they claimed the scanner to be “open source”, so I asked, and while you could buy the kit with or without camera for $83.30 or $116.53 respectively, the company shared a rar file with documentation, and design files, so you could also built it yourself, or modify it. 3D scanner kit content: bq ZUM BT-328 controller board micro USB cable Logitech C270 HD webcam 42-stepper motor 2x Laser 12V/1.5A power supply 8mm Bobbin 4x M3*12 self-tapping screws 2x M3*20 self-tapping screws 10x M3*10 screws 6x M3 nuts 28x M8 nuts 18x M8 washer 2.5mm hexagon wrench 3x M8*30 screws 1x 16014 bearing 2x M8*382mm […]

HE3D K280 Delta 3D Printer Review – Part 2: Upgrades, Calibration, and More 3D Prints

Karl here with part 2 of my experiences with the K280. In the first part of HE3D K280 3D printer review, I spoke about some of the challenges with the K280 getting it calibrated and getting Marlin to work and the initial build. In this part, we are going to look at the new effector, cooling solution I designed, calibration, and general use. If you purchase a machine now you get an injected molded effector and 2 24v cooling fans which HE3D sent over after they saw my initial review. If you purchased a kit before they started including these parts you can pick them up here to upgrade. I would like to point out that this is my first Delta printer. I don’t want to really call this a review but a way to show my experiences. First things first If you purchase this kit I urge you to […]

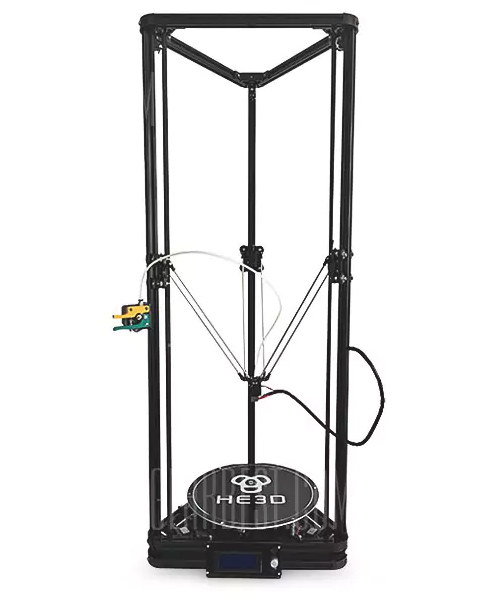

HE3D K280 3D Printer Review – Part 1: Build, Tweaks, and First Prints

Hello Karl here again with another 3D printer review. Today we are looking at an HE3D K280. I saw the brand for the first time on Gearbest a couple months ago and asked for it to review. I never heard of this brand before and have been wanting to review a delta style printer. In my case, I should have been careful what I asked for. It took me quite some time to get it to print utilizing the whole print bed. I experienced several challenges and after defeating them I enjoy this printer quite a bit. Delta style printers mesmerize me with the movements that they make and all the math that goes into moving the extruder in the X, Y and Z. Regular Cartesian printers are rather simple in this respect. Build Volume – 280×600 mm Heated bed No Parts cooling 2020 aluminum and all injected molded parts […]