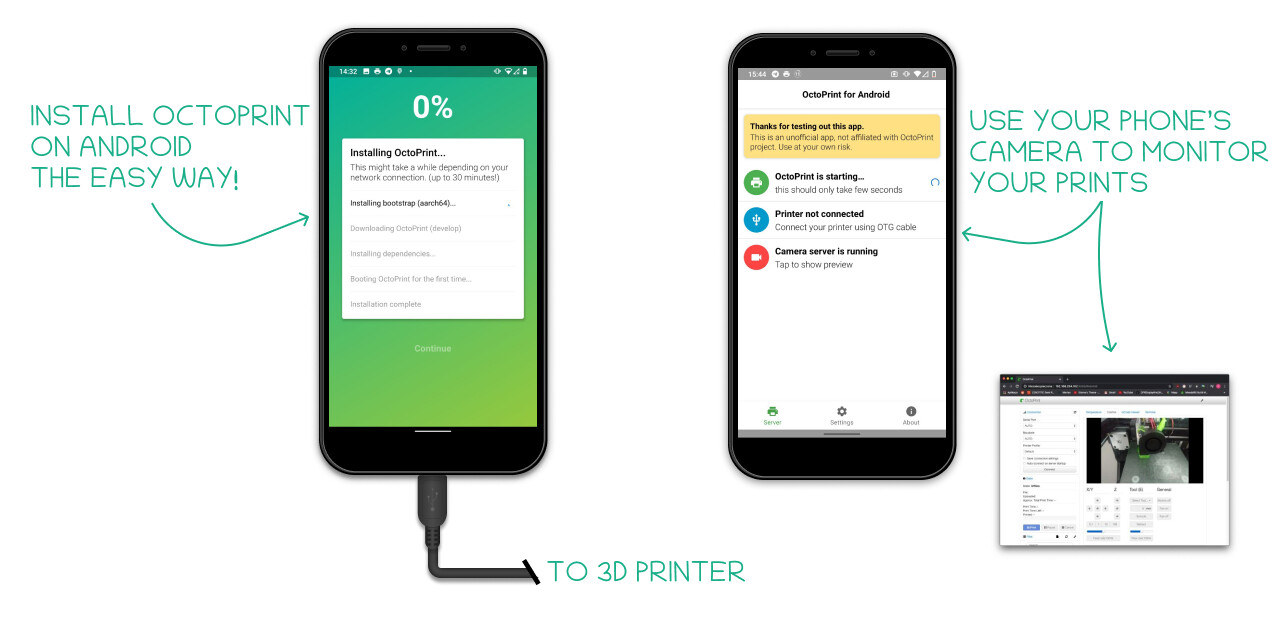

Octoprint is a popular open-source 3D printer controller software that runs on Raspberry Pi boards, Orange Pi Lite SBC, Amlogic TV boxes, and other devices. But considering many people may already an older, perfectly working smartphones at home, FeelFree (Filip) decided to create the Octo4a project that install an Octoprint server on Android smartphones. It makes perfect sense since many smartphones come with a USB OTG interface that can connect to the 3D printer for control, while the touchscreen display is used for the user interface, and the camera to monitor your prints. SSH could be used to access the phone Octoprint server and change the settings manually. You can access the source code and APK files on Github. You’ll need to enable third-party apps in the settings before installing the app in order to install Octoprint on the phone. The only required permission is storage, except if you’d like […]

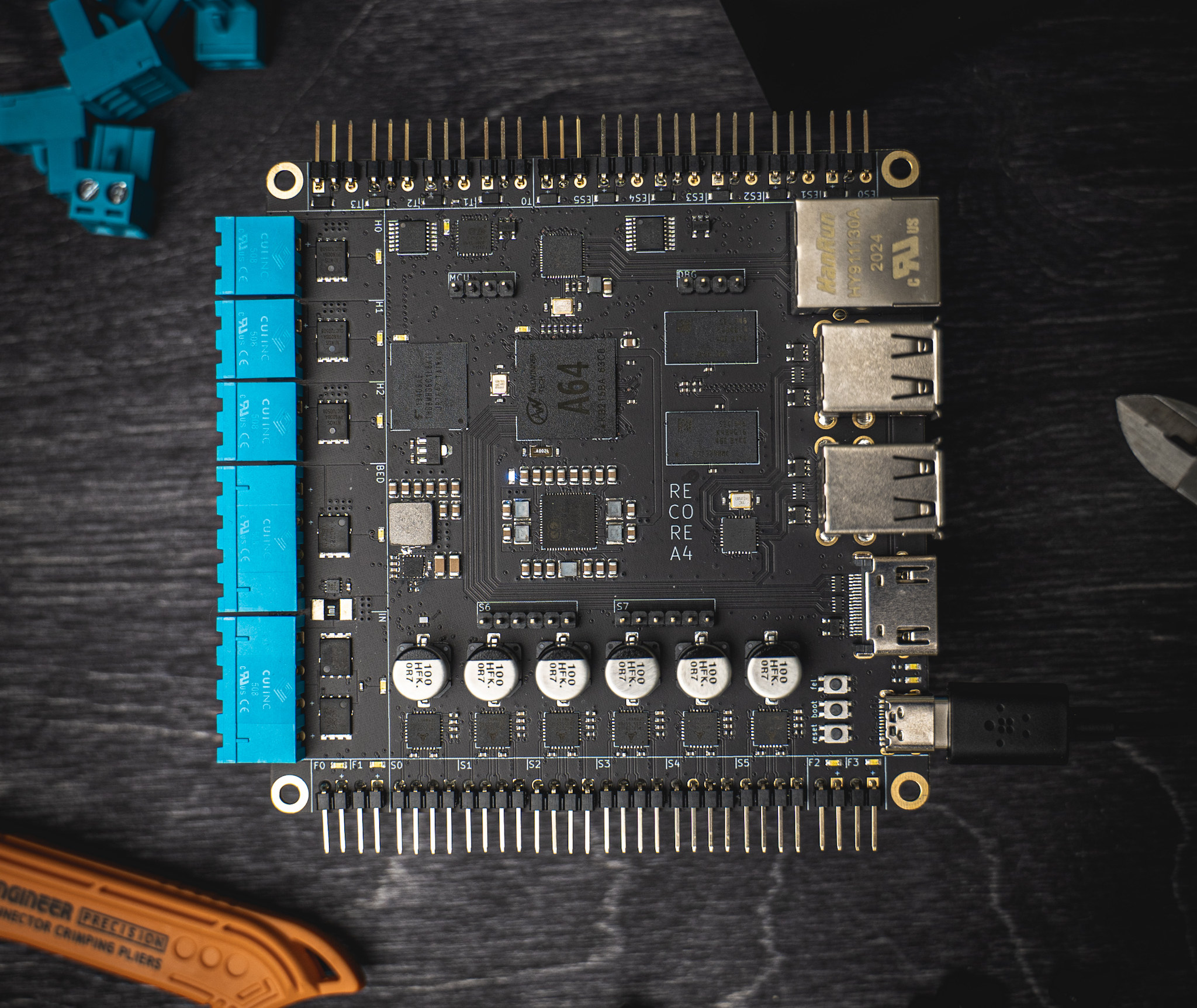

3D printer board leverages Allwinner A64’s AR100 core for real-time control

Elias Bakken has been working on Recore 3D printer control board based on Allwinner A64 processor since 2019 and with revision “A5” of the PCB, Recore is now considered stable and will ship to customers. But wait? Isn’t Allwinner A64 just a quad-core Cortex-A53 processor meant to run Linux? But 3D printer control boards require real-time I/O and that’s why many are designed with STM32, Arduino compatible Microchip MCU or other microcontrollers. The trick here is that Elias did not use the Cortex-A53 cores for real-time control, but instead the 300 MHz AR100 32-bit OpenRISC 1000 core found in Allwinner A64 SoC. Recore specifications: SoC – Allwinner A64 quad-core Cortex-A53 processor running at 1 GHz, with AR100 32-bit core @ 300 MHz, Mali-400MP2 GPU System Memory – 1 GB DDR3 RAM Storage – 8 GB eMMC flash Video Output – HDMI output to connect a display Networking – Gigabit Ethernet […]

How to Use Octoprint on Orange Pi Lite Board, Amlogic S905X and S912 TV Boxes

Karl here. This was article originally going to be how to setup Octoprint 3D printer server on an Orange Pi Lite. But after looking and running through the instructions it seemed like it would be too much so I created an img to simplify things. I also explored running Octoprint on an Amlogic S905x or S912 device and it turned out to be an even better solution. You get a case, power supply, and eMMC flash storage. What is Octoprint? I use Octoprint mainly for its ability to start and stop prints without having to use an sd card. Time lapse is also a nice feature. And one last thing is that I setup a pushbullet notification when it is complete. For a full list of features check out http://octoprint.org/. What is needed? Orange Pi Lite board provided by GearBest for the article, or an Amlogic S905X or S912 Android […]

Creality CR-10 3D Printer Review – Part 2: Tips & Tricks, Octoprint, and Craftware

Hey Karl again with part 2 of my 3D printing experience with the CR-10, after the first part describing CR-10 3D printer setup and first prints. The intent is to share my experiences with the CR-10 with the perspective from a noob. I have to say if you are hard heading like I am, and do a lot of research but don’t fully listen to what you are reading, you are going to waste a lot of filament and time. I spent a couple hours a day for weeks with trial and error and watching the printer and how it works adjusting about a billion settings and testing. I am hoping this will help any current or future CR-10 owner speed up the learning curve. Measuring Filament Diameter The single biggest thing to improve my print quality I found was measuring the filament. I read about this several times but […]