Hey, Karl here and I am getting old. I guess middle age is more accurate. Two wonderful kids and I want to stick around for a while. I have not been feeling well and as a result, I picked up strength training as a form of exercise. I started with an adjustable bench and a set of adjustable dumbbells. I trained with them for about 3 months in my office. I had just enough space. I was hooked. I dove in and learned as much as I could on current best practices, and developed a spreadsheet for tracking progress. I started to outgrow the 55lb/25kg adjustable dumbbells with several exercises and the next step was a squat rack, bar, and Olympic weights. My problem was the lack of space. I had a building that was poorly organized. After a bit of organizing, I was able to carve enough space for […]

Genmitsu Z5-1 fiber laser engraver review

Good day. Karl here. Today I would like to share my experiences with the Genmitsu Z5-1 fiber laser engraver in this review. What is an infrared Galvo laser? A fiber laser is also known as an infrared Galvo laser. Let’s break this combination of words down. Infrared is first. Up to this point, I have reviewed several powerful blue diode lasers for the site. All of them have had 455nm wavelength lasers. In contrast, the Genmitsu Z5-1 laser we are looking at today has a 1064nm wavelength that is outside of the visible spectrum. With infrared, we can mark different materials. Notable plastics and metals are easy to mark with this laser. Galvo is next and was a term I was not familiar with. “Galvo” is a condensed form of “galvanometer.” It’s an electromechanical device used for precise mirror or optical element control in laser and optical systems. Galvanometers are […]

Atezr V35 review – A 35W laser engraver

Karl here. Today let’s look at the Atezr V35 35W diode laser engraver. Atezr is new to the market, at least I am just becoming aware of them, and they asked for a review of one of their machines. This fell in line with the laser power meter project I have been working on, so I accepted, hoping to further along that progress. My goal is to validate the 35W power spec. First, this is 35W optical power….not just the power consumed. You have to be very careful today when shopping for laser engravers. I hate this trend where manufacturers are highlighting total power consumption in marketing materials. This spec is prominently shown in an attempt to trick the consumer into thinking the laser is more powerful than they are. Until starting this review I thought the optical power limit for a single diode laser was 5.5W. I asked Atezr […]

xTool D1 Pro 20W Review – Mandala Art with a 20W laser engraver and cutter

Hey Karl here. I am going to be sharing my experience with the xTool D1 Pro 20W. It is a 20W laser cutter/engraver with a 340x390mm working area. It has been heavily reviewed and I will comment on a few points I have not seen spoken about. I join a lot of Facebook groups for these reviews to get real-world feedback and ideas to write about. With nearly all forms of digital fabrication, I regularly read about misconceptions and frustration that stem from unknowingly purchasing a machine that requires a substantial amount of time and patience to learn. For this review, I kept a daily log and will summarize the time it took me to complete one project. I did get sidetracked on a few aspects and will take that time out. I am excited to share the results of the laser power testing I have been doing. Logs will […]

TerraMaster F4-423 review – A low-power 4-bay NAS tested with Unraid

Hey Karl here. The timing couldn’t have been more opportune when I was asked to review the TerraMaster F4-423 4-bay NAS. Let me explain why. I run Unraid as my OS of choice for my home lab. I have found it easy to maintain and hard to break. My old rig had a 3900X with 3 cores, 6 threads dedicated to docker containers, and the remaining cores running VM’s. It has been a fun and learning experience. I have run it with several different VM configurations over the past few years. The majority of the time I ran 2 VM’s. One personal and one work and I would RDP over to the work VM. If I wanted to game I had a third gaming VM and allocated all resources to it. It’s not super convenient and as convoluted as it sounds. But recently I moved back to my company-provided laptop […]

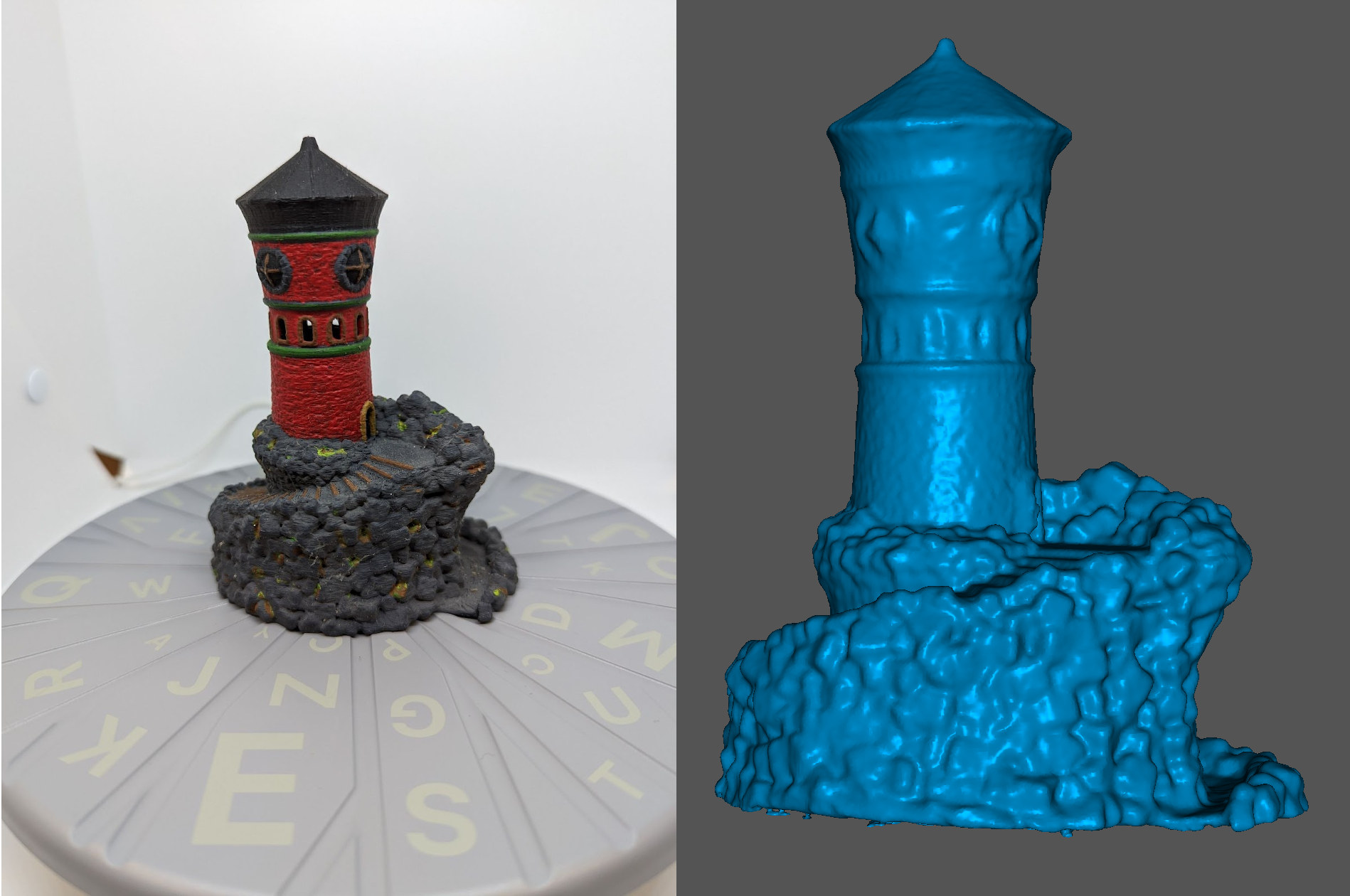

Creality CR-Scan Lizard Review – An easy-to-use 3D scanner

Hey, Karl here, and today we are going to review Creality’s CR-Scan Lizard. This device is a 3D scanner that uses the structured light process to 3D scan. Instead of visible light, it uses non-visible light. I have no idea where lizards come into play but here we are. I have been waiting for quite some time for a lower-cost consumer 3D scanner. I attempted a DIY structured light scanner a long time ago, with some success…..but the time it took was unacceptable. It took me hours to set up perfectly and many more cleaning up point clouds and aligning even for a small scan. Leading me to give up on the project. I search around the Internet periodically but have never found a good working DIY solution. I am glad we are starting to see some relatively good cheapish scanners come out in the past year. Creality CR-Scan Lizard […]

Making a DIY 10.1-inch All-in-One PC out of AMR5 Ryzen 5 gaming mini PC

Hey Karl here. The first thing I need to do is thank the manufacturer of the brand Ace Magician for sending over a unit of their AMR5 gaming mini PC to more or less play with. I did a tiny bit of benchmarking along the way. This is the last time you will see the system in this state 😀 Story time. I have been really wanting a Steam Deck. But we purchased a Nintendo Switch about a year ago and it has barely been used. As soon as my son picked it up he asked why it was so laggy and has shown very little interest in it. So that got me worried about purchasing essentially a one-trick device. There have been a couple of good attempts at a DIY Steam Deck and I wanted to experiment with a small form factor. I went into this with a general […]

Ortur LU2-10A 10W laser module issues and measuring laser power

Karl here and I will keep this short for you. First I will share my experience installing an upgrade module for the Lasermaster 2 Pro, the Ortur LU2-10A. The LM2Pro came with a 5.5w laser module and this upgrade brings the power up to approximately 10w optical power. Spoiler, I am not happy with the kit. [Update (CNXSoft): The company has put us in direct contact with Ortur engineer, and they’ve promised to help us fix the issue. We’ll update the post if/once it is resolved] The Ortur LU2-10A kit comes with a very simple adapter board that appears to do two tasks. 1 is to adapt wiring, and 2, inject additional power for the higher power laser module. It looks like the board will adapt to a lot of different connection types. I followed the instructions and the first time I plugged everything in the laser came on full […]