Arducam Pivistation 5 is an all-in-one Raspberry Pi 5 camera kit that aims to provide a turnkey hardware and software solution to quickly get started with computer vision applications and offered with a choice of camera sensors designed for various applications. The system looks like a Raspberry Pi 5 SBC housed in the official case fitted with a camera. Three models are available, namely the “Hawkeye” featuring a high-resolution 64MP autofocus camera, the “Darksee” with an 8MP camera sensor with ultra low-light sensitivity, and the “Klarity” with a 20MP camera with fixed focus and a large 1-inch sensor. Pivistation 5 specifications All the cameras above rely on a rolling shutter, but the company is also working on the upcoming Arducam Pivistation 5 Swift model that includes a global shutter for robotics applications. Besides the pre-assembled hardware, the Arducam Pivistation 5 family aims to quicken the development process with pre-installed software […]

Ubuntu 24.04 LTS “Noble Numbat” released with Linux 6.8, up to 12 years of support

Canonical has just released Ubuntu 24.04 LTS “Noble Numbat” distribution a little over two years after Ubuntu 22.04 LTS “Jammy Jellyfish” was released. The new version of the operating system comes with the recent Linux 6.8 kernel, GNOME 46, and a range of updates and new features we’ll discuss in this post. As a long-term support release, Ubuntu 24.04 LTS gets a 12-year commitment for security maintenance and support, with five years of free security maintenance on the main Ubuntu repository, and Ubuntu Pro extending that commitment to 10 years on both the main and universe repositories (also free for individuals and small companies with up to 5 devices). This can be extended a further 2-year, or 12 years in total, for Ubuntu Pro subscribers who purchase the Legacy Support add-on. Canonical explains the Linux 6.8 kernel brings improved syscall performance, nested KVM support on ppc64el, and access to the […]

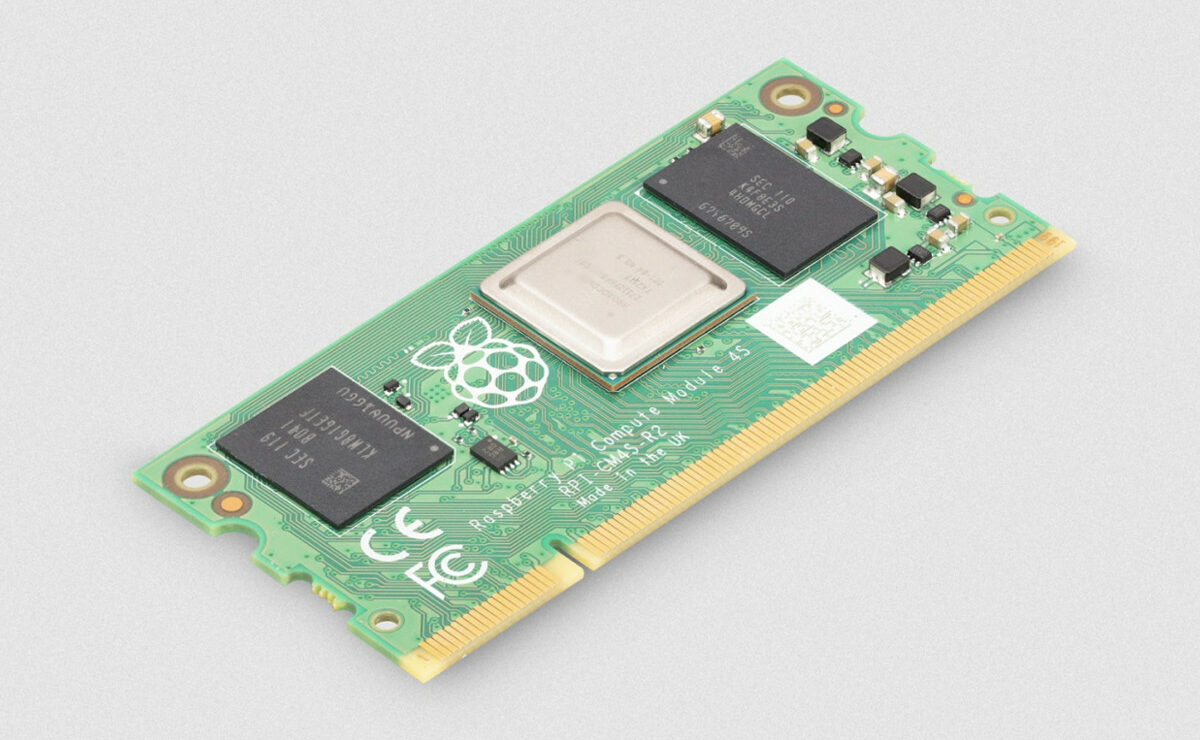

Raspberry Pi CM4S module gets 2GB, 4GB, and 8GB RAM variants for commercial products

Raspberry Pi has announced three new versions of its Compute Module 4S (CM4S) offering 2GB, 4GB, and 8GB RAM options which is an upgrade from the 1GB variant introduced in 2022. These new modules feature the same Broadcom BCM2711 quad-core Cortex-A72 SoC used in Raspberry Pi 4 and Raspberry Pi CM4 and have a starting price of only $25. The main downside is that the modules can only be purchased in bulk (200-unit boxes) through Raspberry Pi Approved Resellers. Raspberry Pi Compute Module 4S (CM4S) specifications: SoC – Broadcom BCM2711 CPU – Quad-core 64-bit Cortex-A72 processor @ 1.5 GHz GPU – VideoCore VI GPU 3D Graphics: OpenGL ES 3.0 and Vulkan 1.1 Video H.265 (HEVC) (up to 4Kp60 decode) H.264 (up to 1080p60 decode, 1080p30 encode) Memory – 1GB, 2GB, 4GB, and 8GB LPDDR4-3200 SDRAM with ECC Storage – 8GB, 16GB, or 32GB eMMC flash; Option for 0GB eMMC Flash […]

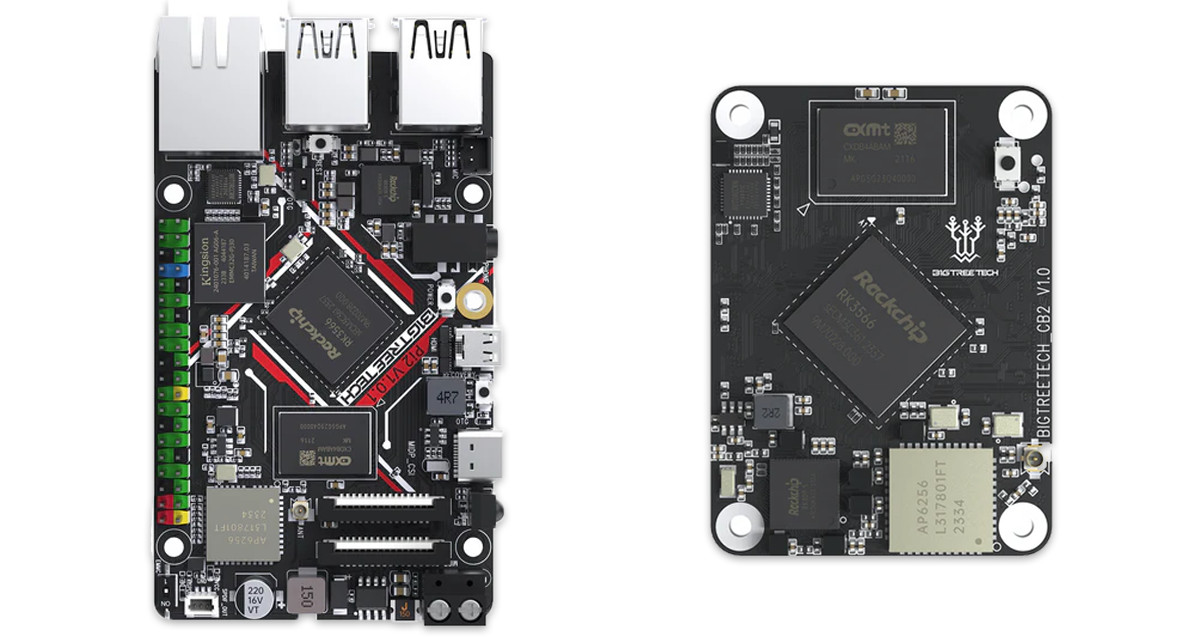

BIGTREETECH Pi 2 SBC and CB2 module for 3D printers now feature Rockchip RK3566 SoC with Gigabit Ethernet

BIGTREETECH recently announced the release of the BIGTREETECH Pi 2 SBC and BIGTREETECH CB2 SoM, both powered by the Rockchip RK3566 SoC. These new modules are direct upgrades from the BIGTREETECH Pi v1.2 and BIGTREETECH CB1, which we covered and reviewed in our previous posts. Specially designed for 3D printers, these new modules have a similar form factor to that of a Raspberry Pi and the RPI CM4 module, and come with a set of upgraded features including support for GbE Ethernet, dual-band WiFi, up to 32GB of LPDDR4 RAM, eMMC storage, HDMI, USB, and more. BIGTREETECH Pi 2 Specifications SoC – Rockchip RK3566 CPU – Quad-core Arm Cortex-A55 processor @ 1.8 GHz GPU – Arm Mali G52-2EE GPU with support for OpenGL ES 1.1/2.0/3.2, Vulkan 1.1, OpenCL 2.0 NPU – 0.8 TOPS AI accelerator VPU – 4Kp60 H.265/H.264/VP9 video decoding, 1080p100f H.265/H.264 video encoding System Memory – 2GB LPDDR4 (Customizable – 1GB/2GB/4GB/8GB) […]

Louder Raspberry Pi is an open-source home media center that is powered by Raspberry Pi Zero and a TI TAS5805M DAC

Louder Raspberry Pi is an open-source home media center based on a combination of the Raspberry Pi Zero W or Zero 2 W and the Texas Instruments TAS5805M DAC. It is an audio entertainment platform created by Andriy Malyshenko of Sonocotta, a Polish electronics hobbyist and maker. Louder Raspberry Pi incorporates the computing power of the Raspberry Pi Zero and the Hi-Fi audio processing capabilities of TI’s TAS5805M DAC in a compact, aluminum case. The device delivers up to 25W per channel stereo output and is powered via a 65W+ USB-C PD3.0 adapter. It is “aimed to be paired with medium-to-large speaker systems” and supports both Wi-Fi and Ethernet. The Raspberry Pi board was selected over other lightweight alternatives due to the ease of development it offers. The Raspberry Pi Zero board is small enough to make for an overall compact device and powerful enough to handle the demands of […]

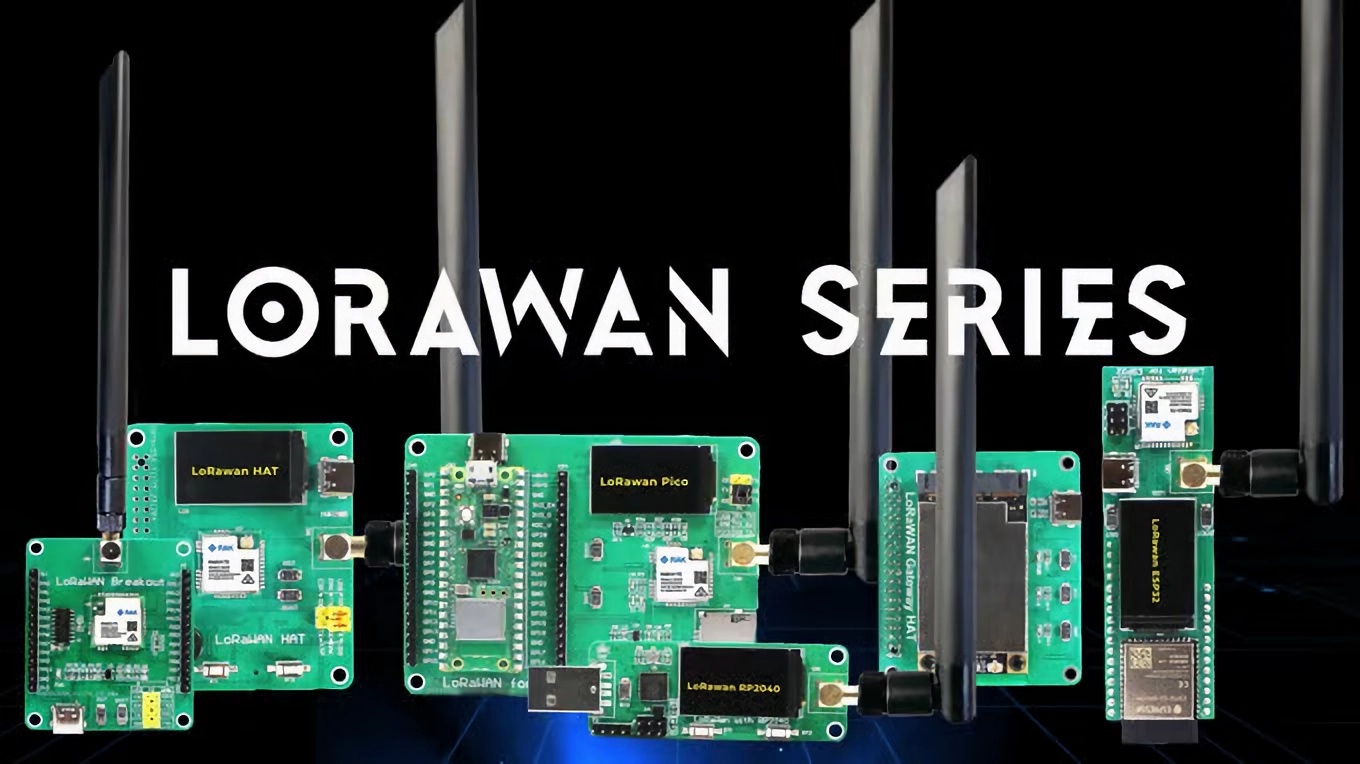

SB Components LoRaWAN gateways and nodes are made for Raspberry Pi and ESP32 boards (Crowdfunding)

UK-based hardware developer, SB Components, has designed a new LoRaWAN product series (gateways and nodes) for the Raspberry Pi SBCs, Raspberry Pi Pico, ESP32, and other hardware, based on RAKWireless RAK5146 and RAK3172 modules. The products are available in up to five variants (plus two relay boards) and are built to cater to hobbyists with different needs. They support several LoRaWAN server platforms including The Things Stack, Chirpstack, and Helium, with adaptive spreading factors, coding rates, and bandwidth configurations. The LoRaWAN products include: Gateways – RAK5146 LoRaWAN Gateway HAT and RAK3172 LoRaWAN Gateway HAT for the Raspberry Pi SBCs Nodes – RAK3172 LoRaWAN Module (Powered by Raspberry Pi Pico), Raspberry Pi RP2040 USB Dongle, RAK3172 LoRaWAN Module (powered by ESP32), LoRaWAN Breakout, GatePi LoRaWAN 4-Ch Relay, GatePi LoRaWAN 8-Ch Relay LoRaWAN (long-range wide access network) uses the LoRa modulation technique to transmit data over large distances. In a LoRAWAN network, […]

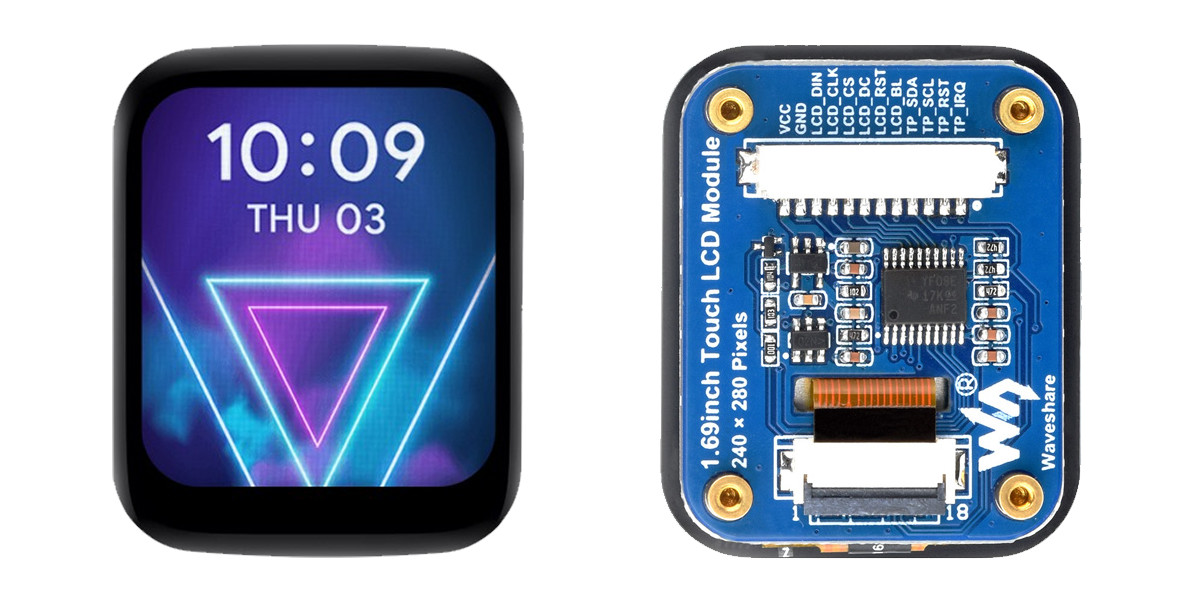

$15 Waveshare 1.69-inch IPS touch LCD module works with Raspberry Pi, Arduino, ESP32, STM32, and other platforms

The Waveshare 1.69-inch IPS touch LCD is a 1.69-inch rounded display with 240×280 resolution and a 262K color range. The display driver (ST7789V2) and touch controller (CST816T) are integrated on-board and rely on SPI and I2C interfaces that make it compatible with popular platforms such as Raspberry Pi, Arduino, ESP32, STM32, and more. Previously we have covered many similar display modules like the MaTouch ESP32-S3, T-RGB ESP32-S3, and ESP32-S3 Round SPI TFT. Feel free to check these out if you are looking for a specific rounded display product. Waveshare 1.69-inch IPS touch LCD specifications Display 1.69-inch round LCD with 240×280 resolution and IPS panel. 262K color depth Display Driver – ST7789V2 SPI display driver Touch Control – CST816T I2C capacitive touch controller for responsive input. Onboard Logic Level Converter – Onboard voltage translator for 3.3V/5V power, works with Raspberry Pi, ESP32-S3, Raspberry Pi Pico, Arduino, STM32, and more. Dimensions – 41.13 x 33.13 […]

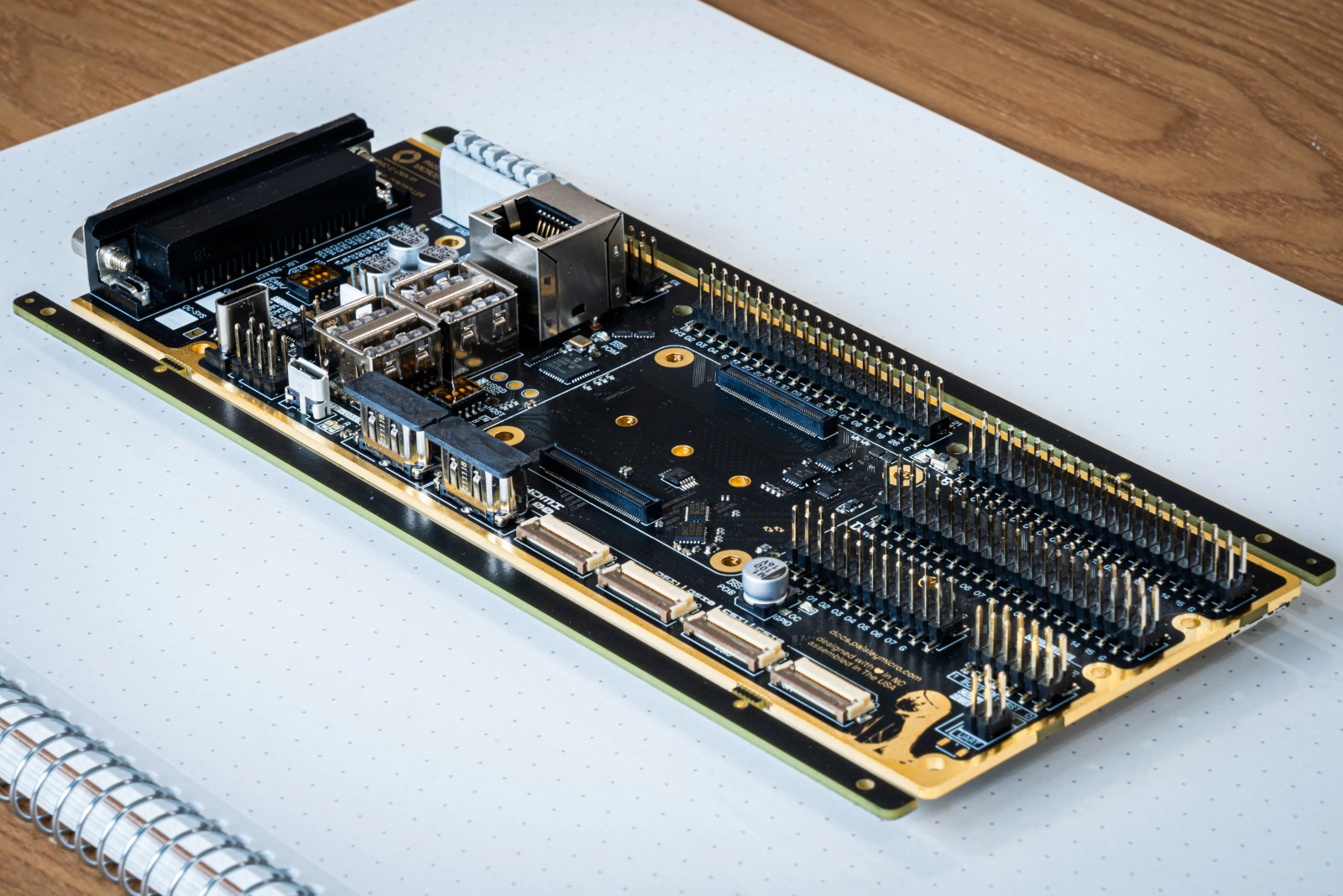

Industrial control board combines Raspberry Pi CM4/CM5 with STM32H7 MCU for real-time control

Paisley Microsystems PMC-C-CMX is a DIN-Rail mountable industrial control board taking a Raspberry Pi CM4 or CM5 (once launched), equipped with an STM32H7 Arm Cortex-M7 microcontroller for real-time control. The carrier board integrates features such as wide voltage input (7 to 55V DC), an M.2 PCIe Gen 3 Key-B and Key-M sockets with cellular option, gigabit Ethernet, HDMI and MIPI DSI display interfaces, twp MIPI CSI camera interfaces, and several headers and connectors with RS485, GPIO, I2S, SPI, and more connected to either the Raspberry Pi Compute Module or the STM32H7 MCU. Paisley Microsystems PMC-C-CMX specifications: Supported system-on-modules – Raspberry Pi CM4 or upcoming Raspberry Pi CM5 MCU – STMicro STM32H7B0 Arm Cortex-M7 microcontroller up to 280 MHz with 128KB flash, 1.4MB SRAM MCU <-> CM communication – UART and/or SPI Video Output 2x HDMI ports up to 4Kp60 2x MIPI DSI connectors Camera input – 2x MIPI CSI connectors […]