We’ve already checked out the specifications, and gone through an unboxing and a teardown of the GEEKOM XT12 Pro mini PC in the first part of the review, so we’ll now report our experience with the 12th Gen Intel Core i9-12900H mini PC with Windows 11 Pro operating system. In this second part of GEEKOM XT12 Pro, we’ll test the features of the Alder Lake mini PC in Windows 11 Pro, run benchmarks, test networking and storage, evaluate cooling performance, and finally provide some numbers for fan noise and power consumption. Software overview and features testing The System->About menu confirms that we have an XT12 Pro mini PC with a 12th Gen Intel Core i9-12900H processor clocked at 2.50 GHz (base frequency) and 32GB RAM that runs Windows 11 Pro operating system version 23H2. The system was tested with Windows 11 OS build 22631.3447. HWiNFO64 program provides more details about […]

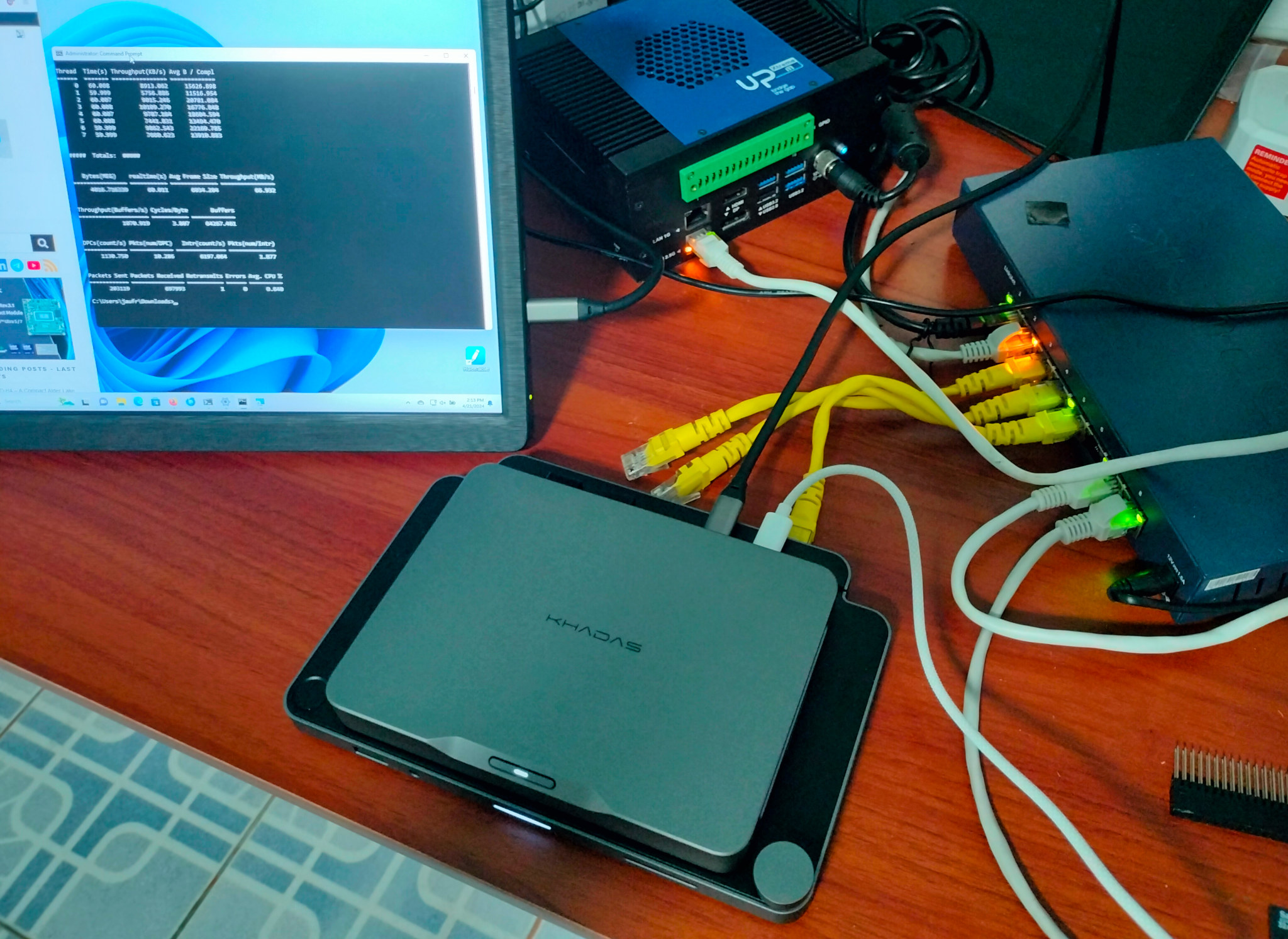

Testing ntttcp as an iperf3 alternative in Windows 11 (and Linux)

ntttcp (Windows NT Test TCP) is a network benchmarking utility similar to iperf3 that works in both Windows and Linux written and recommended by Microsoft over iperf3, so we’ll test the alternative in this mini review. iperf3 is a utility of choice for our reviews of single board computers and mini PCs running either Windows or Linux, but we’ve noticed that while Ethernet (up to 2.5GbE) usually performs just as well in Windows and Linux, WiFi is generally much faster in Ubuntu 22.04 than in Windows 11. So when XDA developers noticed a post by Microsoft saying iperf3 should not be used on Windows 11, it caught my attention. Microsoft explains iperf3 should not be used in Windows for three main reasons: The maintainer of iperf – ESnet (Energy Sciences Network) – says “iperf3 is not officially supported on Windows, but iperf2 is. We recommend you use iperf2. Some people […]

“MaUWB_DW3000 with STM32 AT Command” Review – Using Arduino to test UWB range, precision, indoor positioning

Hello, the device I am going to review is the MaUWB_DW3000 with STM32 AT Command. This is an Ultra-wideband (UWB) module from MakerFabs. The core UWB module on this board is the DW3000 UWB transceiver, and it is also equipped with an ESP32 microcontroller programmable with the Arduino IDE, as well as OLED display. The manufacturer claims that this UWB board resolves multiple anchors and tags mutual conflicts and supports up to 8 anchors and 64 tags. Additionally, the manufacturer has added an STM32 microcontroller to handle UWB multiplexing, allowing users to control the core UWB module by simply sending AT commands from an ESP32 microcontroller to the STM32 microcontroller. More information about this UWB board can be found on the manufacturer’s website. “MaUWB_DW3000 with STM32 AT Command” unboxing MakerFabs sent the package to me from China. Inside the package, there were 4 sets of the MaUWB_DW3000 with STM32 AT […]

Review of GEEKOM XT12 Pro (Intel Core i9-12900H) Mini PC – Part 1: Specs, unboxing, and teardown

GEEKOM XT12 Pro is a Windows 11 Pro mini PC powered by a 12th Gen Intel Core i9-12900H 14-core Alder Lake processor clocked up to 5 GHz with support for 8K video output, up to four 4K displays, 2.5Gbps Ethernet, and a WiFi 6E and Bluetooth 5.2 wireless module. The mini PC supports up to 64GB DDR4 memory, 2TB M.2 NVMe SSD, and 1TB M.2 SATA SSD, and also comes with multiple USB ports (USB4, USB 3.2, and USB 2.0), a 3.5mm stereo audio headset jack, and a Kensington lock slot. GEEKOM has sent us an XT12 Pro mini PC with 32GB RAM and a 1 TB M.2 NVMe SSD for review. Today, we’ll go through the GEEKOM XT12 Pro specifications, do an unboxing to check the mini PC’s ports and accessories, perform a teardown to understand the hardware design better, and finally give it a try with Windows 11 […]

Testing Cytron MAKERDISK M.2 NVMe SSDs on Raspberry Pi 5 with GEEKWORM X1001 and Waveshare M.2 PCIe HAT+

Cytron has sent us a few of their MAKERDISK NVMe SSDs preloaded with Raspberry Pi OS so that we can test them on a Raspberry Pi 5 SBC, either with a GEEKWORM X1001 or Waveshare M.2 PCIe HAT+ add-on boards both of which were also provided by the company. Ever since the first M.2 PCIe HATs for the Raspberry Pi 5 were released, we knew Raspberry Pi Limited was working on its own model, and based on some Twitter/X “rumors” (with photos) the launch of the official M.2 HAT+ should be just around the corner. So it’s the perfect timing to test some SSDs on the Raspberry Pi 5 even though I’ve yet to get the official HAT+ Cytron “MAKERDISK” package unboxing The Malaysian company sent me a kit with everything I needed to get started, minus the Raspberry Pi 5 I already owned. This includes 128GB or 256GB NVMe […]

Kamvas Pro 16 (2.5K) review – A 15.8-inch drawing tablet and stylus with 8192 levels of pressure sensitivity

HUION Kamvas Pro 16 (2.5K) is a 15.8-inch drawing tablet with 2.5K resolution that comes with a stylus supporting 8192 levels of pressure. The company sent us a review sample, so I’ll test it as an external display in Windows 11 and Ubuntu 22.04, and check the drawing functions of the Kamvas Pro 16 with the stylus as well as other potential use cases. Kamvas Pro 16 (2.5K) specifications (model GT1602) But before that, let’s list the specifications of the display: Panel – 15.8-inch (diagonal) IPS display at 60 Hz Resolution – 2560 x 1440 (16:9) QHD PPI (Pixels Per Inch) – 186 Active Area – 349.6 x 196.7 mm Contrast Ratio – 1200:1 Brightness – 220nit (Max.) Response Time – 14ms Viewing Angle – 178° (89°/89°(H)/89°/89°(V) (Typ.)(CR>10)) Color Gamut Volume – 145% sRGB Color Gamut Coverage – 99% sRGB / 99% Adobe RGB Colors – 16.7M (8-bit) Surface Finish […]

Review of Purple Pi OH – A Rockchip RK3566 SBC tested in 2GB/16GB and 4GB/32GB configurations

Hello, I am going to review the Purple Pi OH boards from Wireless-Tag. The Purple Pi OH is a single-board computer (SBC) mechanically compatible with the Raspberry Pi. They are designed for personal mobile Internet devices and AIoT devices, which can be used in various applications, such as tablets, speakers with screens, and lightweight AI applications. The manufacturer sent me two models. The first model is the Purple Pi OH, which is equipped with 2GB of memory and 16GB of storage space and supports 2.4GHz Wi-Fi. The second model is the Purple Pi OH Pro, equipped with 4GB of memory and 32GB of storage space. This board supports both 2.4GHz and 5GHz Wi-Fi. The other components of both devices are almost the same. They are powered by the Rockchip RK3566 chip, which integrates a quad-core Cortex-A55 processor up to 1.8 GHz, a Mali-G52 GPU from Arm for 3D graphics acceleration, […]

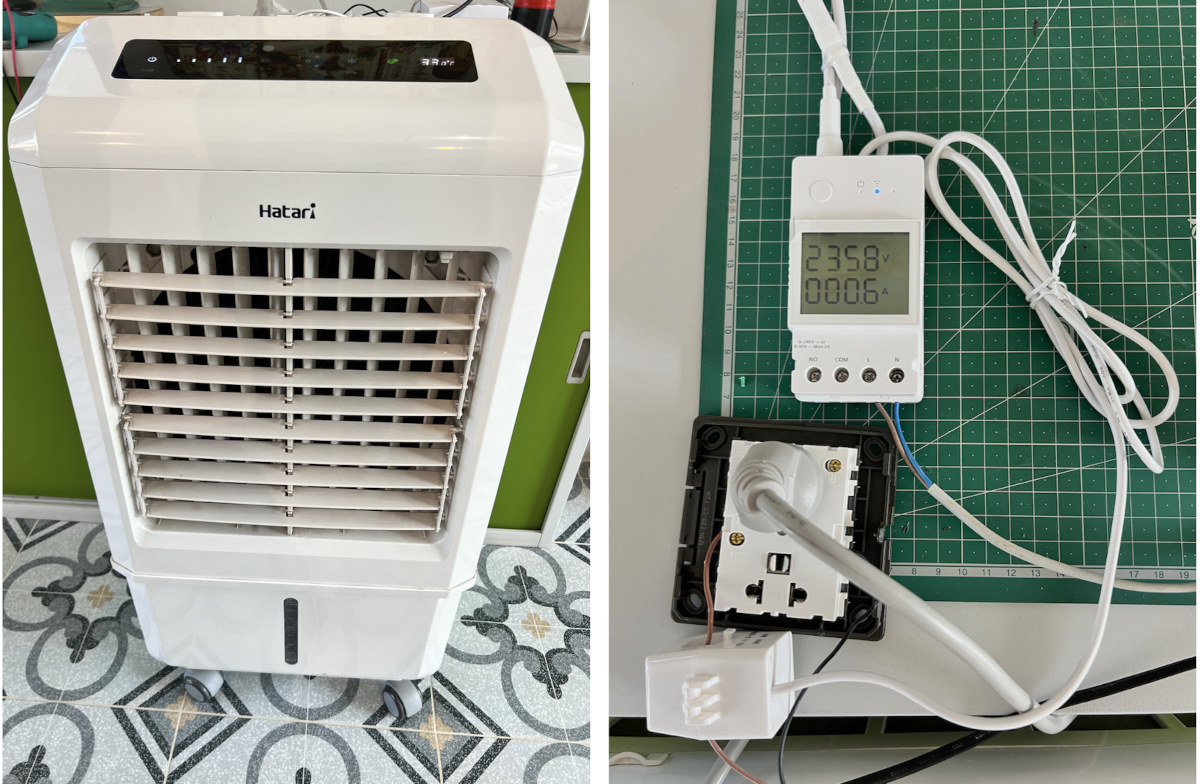

SONOFF POW Ring Review – A WiFi CT Clamp power meter tested with eWelink and Home Assistant

The trend of measuring the energy usage of household electrical devices has become increasingly popular among Smart Home users in the past few years. We have received the new SONOFF POW Ring Smart Power Meter Switch device for review from ITEAD. Unlike SONOFF’s existing energy monitoring devices such as POW Elite, SPM, DualR3, POW3, and POW Origin, this new device, also called POWCT, utilizes a current transformer (CT) to measure the current flow, or total power being consumed. This method provides no physical contact with live wires and reduces the risk during installation. Additionally, it can measure currents of up to 100A, which is significantly higher than previous models. This makes it suitable for measuring electricity usage at the main circuit breaker, energy generated from solar panels, or even for Electric Vehicle (EV) home chargers. The SONOFF POW Ring, which we are testing today, is not only a Smart Power […]