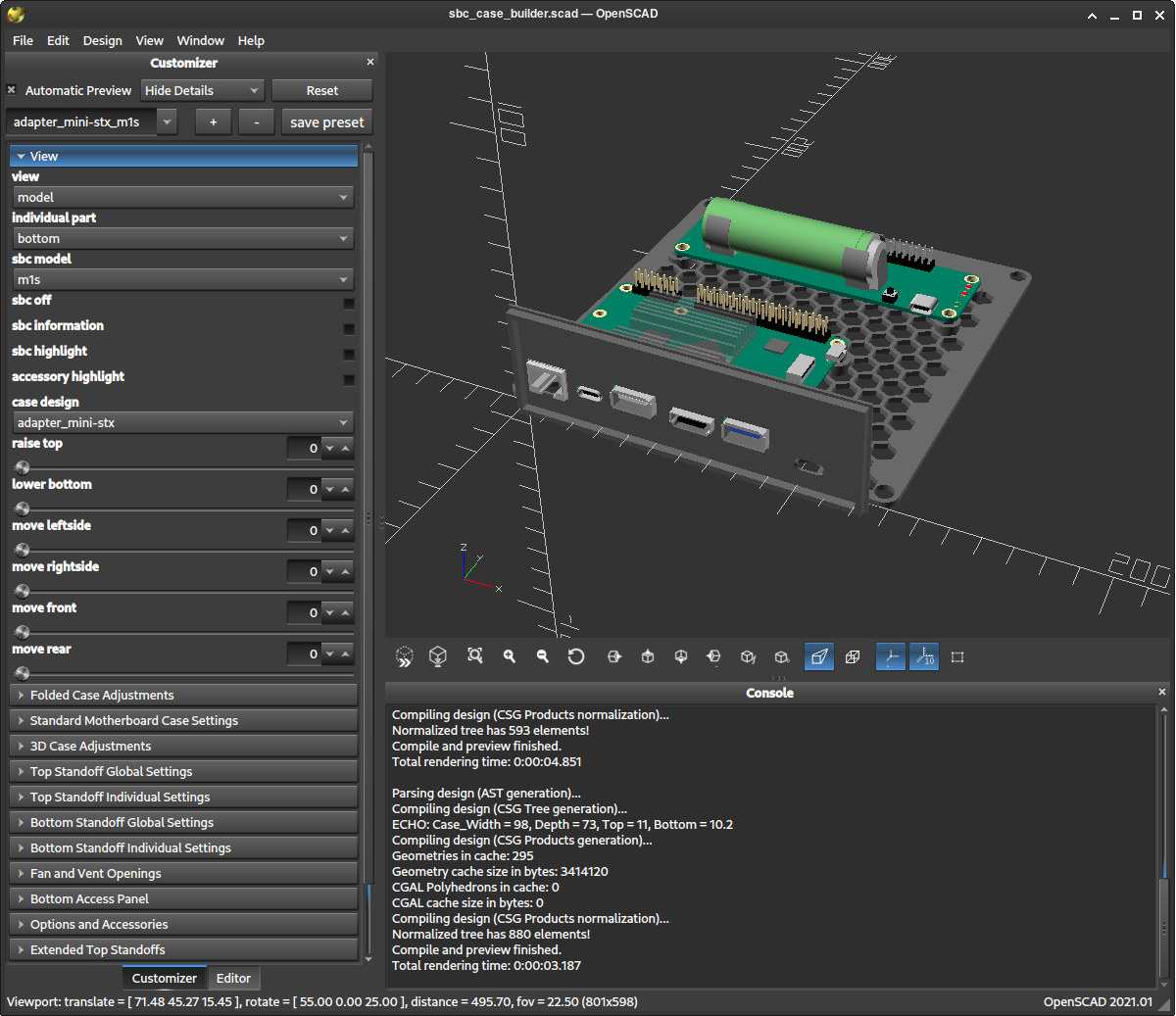

SBC Case Builder V3.0 case design utility has just been released with the ability to create over 1,000 standard cases – not including customization – for popular SBCs from Raspberry Pi, Hardkernel, Orange Pi, Radxa, and others, as well as standard motherboards following Mini-ITX, Pico-ITX, NUC, Nano-ITX, etc.., and SBC adapters following these standards, meaning you could install a Raspberry Pi 5 into a mini-ITX case if needed. SBC Case Builder started as a command line utility for designing DIY case for SBCs relying on OpenSDAD in April 2022, but Edward Kisiel (hominoids) quickly released version 2 with a GUI in October or the same, and has now further improved the utility with the release of SBC Case Builder v3.0. Version 3.0 comes with many improvements but the main focus was to reuse existing and new PC standard form factor cases by creating SBC adapters and custom I/O Shields since […]

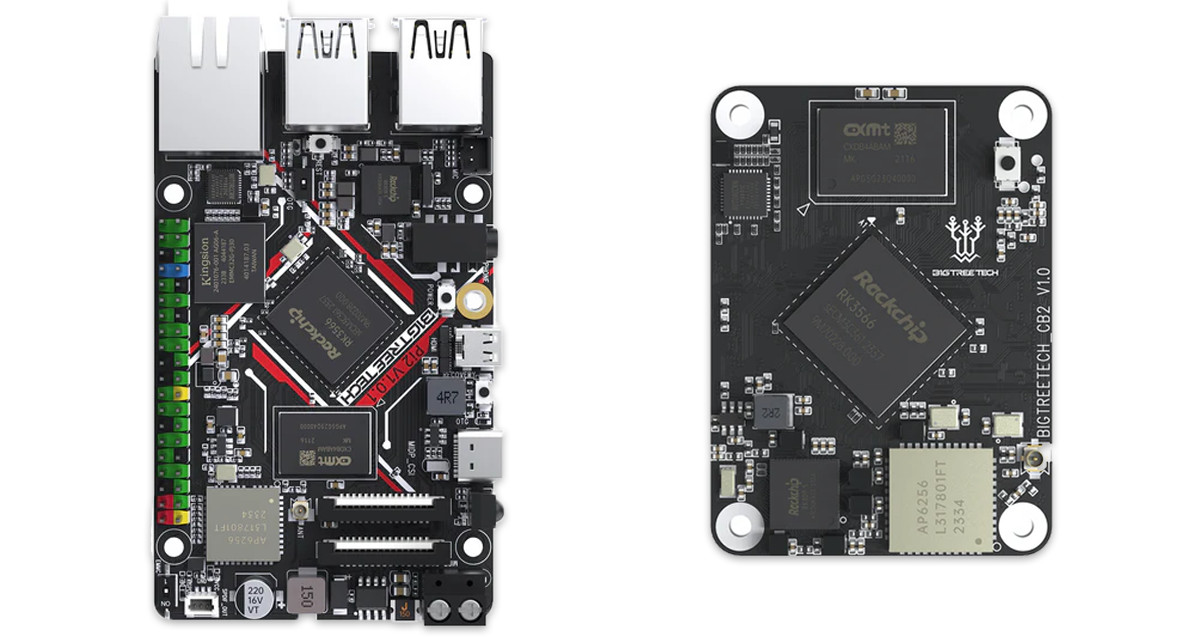

BIGTREETECH Pi 2 SBC and CB2 module for 3D printers now feature Rockchip RK3566 SoC with Gigabit Ethernet

BIGTREETECH recently announced the release of the BIGTREETECH Pi 2 SBC and BIGTREETECH CB2 SoM, both powered by the Rockchip RK3566 SoC. These new modules are direct upgrades from the BIGTREETECH Pi v1.2 and BIGTREETECH CB1, which we covered and reviewed in our previous posts. Specially designed for 3D printers, these new modules have a similar form factor to that of a Raspberry Pi and the RPI CM4 module, and come with a set of upgraded features including support for GbE Ethernet, dual-band WiFi, up to 32GB of LPDDR4 RAM, eMMC storage, HDMI, USB, and more. BIGTREETECH Pi 2 Specifications SoC – Rockchip RK3566 CPU – Quad-core Arm Cortex-A55 processor @ 1.8 GHz GPU – Arm Mali G52-2EE GPU with support for OpenGL ES 1.1/2.0/3.2, Vulkan 1.1, OpenCL 2.0 NPU – 0.8 TOPS AI accelerator VPU – 4Kp60 H.265/H.264/VP9 video decoding, 1080p100f H.265/H.264 video encoding System Memory – 2GB LPDDR4 (Customizable – 1GB/2GB/4GB/8GB) […]

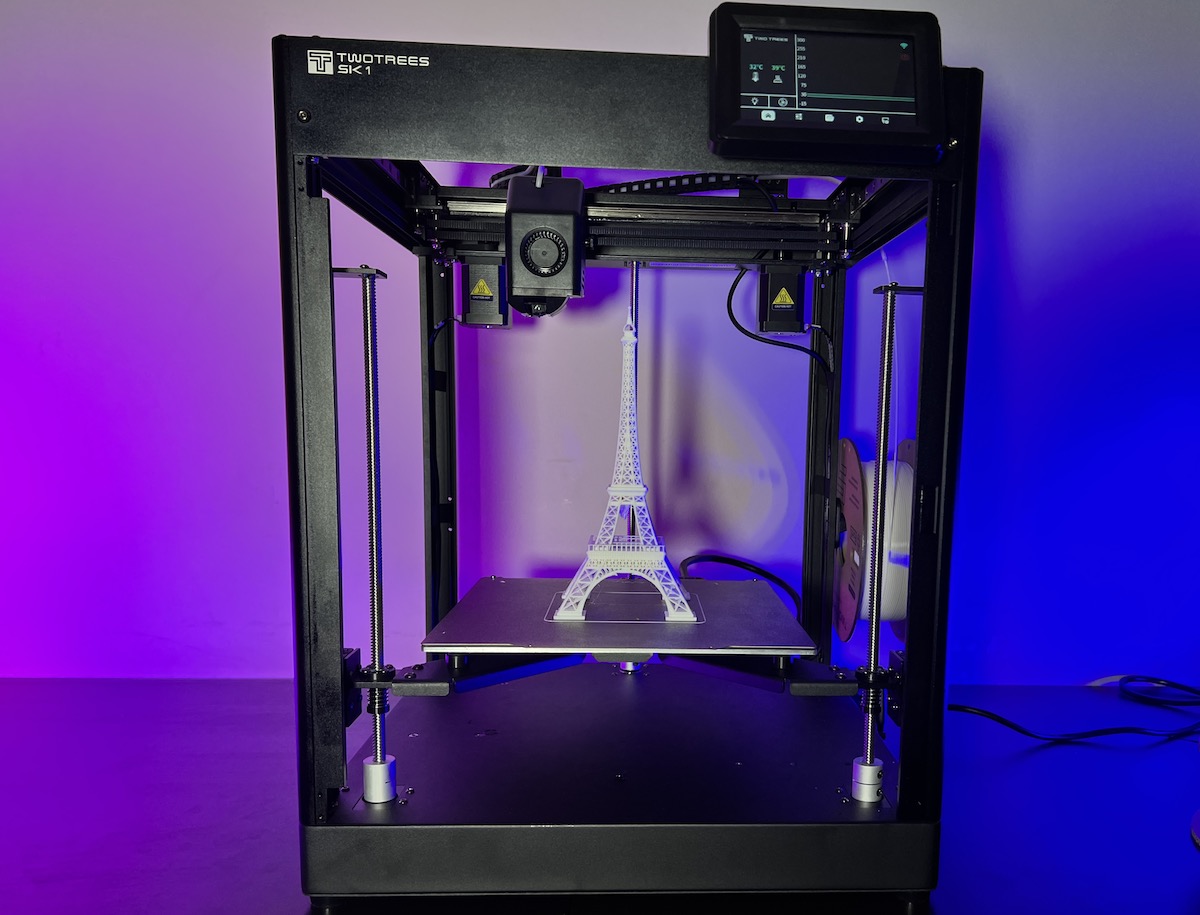

TwoTrees SK1 review – A CoreXY 3D printer with high printing speeds

TwoTrees SK1 is an FDM 3D printer with a working area of 256 x 256 x 256 mm and a CoreXY system that can print 3 to 5 times faster than a typical 3D printer. The movements of a CoreXY 3D printer are achieved by moving two motors simultaneously. The TwoTrees SK1 CoreXY 3D printer can print at a maximum speed of 700 mm/s and features automatic Z-Tilt base leveling with a 36-point mesh bed. The print head uses a dual-gear direct extruder to feed the filament directly to the nozzle and the nozzle supports up to 300 degrees Celsius. The printer also comes preloaded with the popular Klipper firmware. TwoTrees SK1 specifications Printing size – 256 x 256 x 256 mm Dimensions – 400 x 400 x 530 mm Printing speed – Up to 700mm/s Acceleration – Up to 20,000 mm/s2 Nozzle temperature – Up to 300ºC Guide rail […]

Lite3DP Gen 2 is a tiny, open-source resin 3D printer (Crowdfunding)

The Lite3DP Gen 2 3D Printer builds on the success of its predecessor. With a new and improved design, an ESP32 microcontroller replacing the Arduino Pro Mini, and several other improvements, the Lite3DP Gen 2 is well-suited for making small, detailed resin prints. It is slightly bulkier than the Lite 3DP S1 3D printer but is still compact enough to fit into a bag. Gen 2 has been designed to maintain backward compatibility with the older model, and owners of existing Lite3DP printers can use the Gen 2 dev kit to upgrade their printers. The resin 3D printer is completely open-source (firmware, hardware, and software), and you can use the schematics, Gerber files, code, and other resources hosted in the GitHub repository to build a different kind of mSLA resin printer. Lite3DP Gen 2 key features & specifications: Electronics – All-in-one PCB with ESP32 microcontroller, high-res LCD, an ultra-silent TMC2209 […]

AirGradient ONE Kit Review – An open-source indoor air quality monitor

The product we are reviewing today is the “AirGradient ONE” air quality monitor kit which is an updated version of the earlier AirGradient air quality monitor. The device is equipped with sensors from Sensirion and Plantower, allowing it to measure many air quality parameters such as CO2, PM2.5, TVOCs, NOx, temperature, and humidity. It is an indoor air quality monitor that is both open-source software and open hardware. This means that the Arduino source code, schematic diagrams, PCB, and 3D models of the enclosure are available to developers. AirGradient ONE DIY Kit Unboxing The device was packaged within a cardboard box, with a greeting card from the manufacturer. The card features a QR code linking to a webpage with the installation guide. Since I requested the Kit version (there’s also a fully assembled model), some sensors were not pre-assembled and they were well-packaged in separate seals. The main PCB was […]

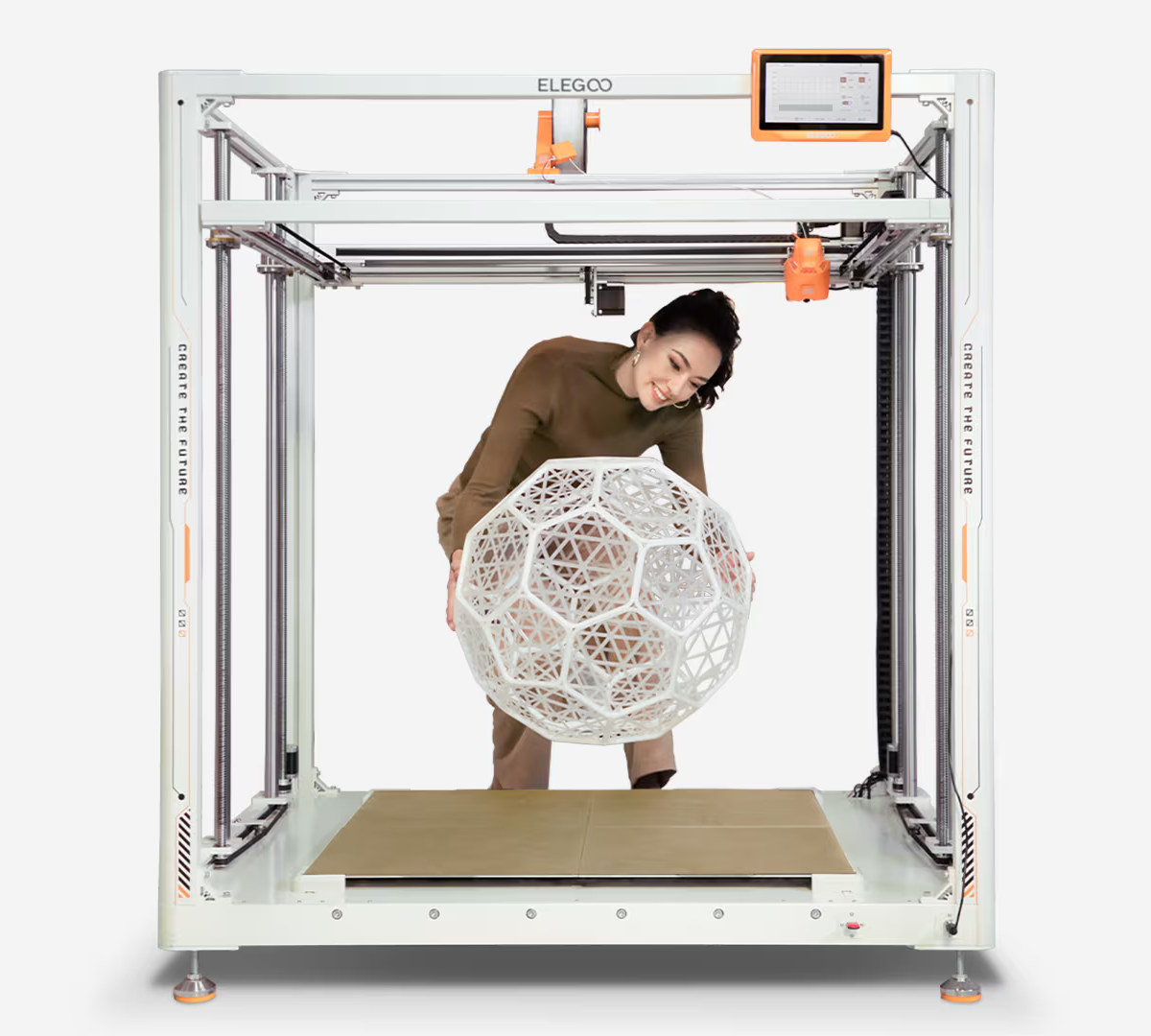

ELEGOO OrangeStorm Giga is an enormous 3D printer that supports up to four nozzles (Crowdfunding)

If you’ve found yourself frustrated more than once because the build volume of your 3D printer was too small for your prints, the ELEGOO OrangeStorm Giga should meet most people’s requirements as the enormous 3D printer offers an 800 x 800 x 1,000mm building volume, and can also be fitted with four nozzles and filament spools to print multiple objects at the same time. Besides the ability to print larger objects and multiple objects, you won’t need to find a table for it, since the gigantic 3D printer would typically be installed on the floor. Those large 3D printers have been available to businesses for years, but it’s the first time I’ve seen a consumer-grade 3D printer with those dimensions! ELEGOO OrangeStorm Giga specifications: Build Volume – 800 x 800 x 1,000mm Nozzle Maximum Temperature – 300°C Nozzle Diameter – 0.6mm Number of nozzles – 1, expandable to 4 Hot […]

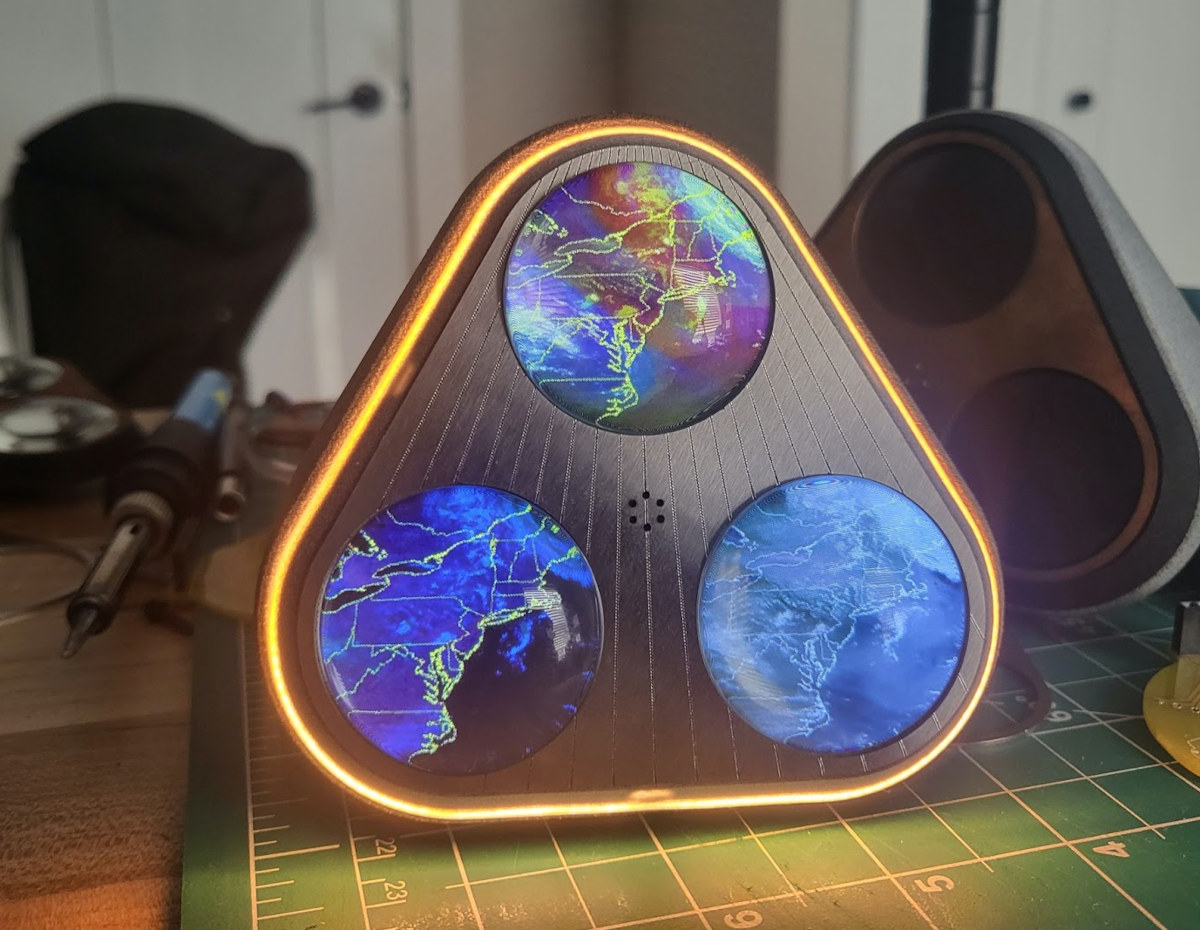

Raspberry Pi Zero W-based Weather Orbs shows weather data on three round displays (Crowdfunding)

Peter Holderith’s Weather Orbs is a Raspberry Pi Zero W-powered desktop weather station that displays animated weather data from NOAA and NWS on three small round displays connected over SPI. Internally it’s an add-on board that connects to the 40-pin GPIO header of the Raspberry Pi Zero W and with three additional headers to connect the smartwatch round displays. The PCB also comes with 16 RGB LEDs to create some nice lighting effects. The Raspberry Pi Zero W and accompanying electronics are housed in a custom “high-quality” 3D printed enclosure with a cover made of brushed stainless steel, and thick glass magnifiers complete the design for a retro style. The default firmware fetches weather data, such as live satellite images from NOAA or radar from NWS, and displays those on the three round displays. It also starts a Wi-Fi hotspot called “weatherorbs” to which the user can connect and then […]

Review of BIGTREETECH Pad 7 Klipper pad with Creality Ender-3 Pro S1 3D printer

I received the BIGTREETECH Pad 7 7-inch Klipper pad and tablet PC for review earlier this month. I’ve already tested it with a Raspberry Pi CM4 as a Linux tablet PC with touchscreen, and I’ve now reinstalled the BTT CB1 Allwinner H616 system-on-module to run the pre-install Klipper OS and connect the Pad 7 to a Creality Ender-3 Pro S1 3D printer. When I first booted the Pad 7 it ended up with an error message from Klipper complaining about a missing configuration file. I connected to WiFi and update all software packages, but it didn’t help. It’s just because the Pad 7 needs to be configured for a specific printer. We can do so through the web dashboard accessible through a web browser going to http://btt-pad7.local (unless you’d changed the hostname in the system) We’ve got the same error shown in the web interface as Klipper needs to be […]