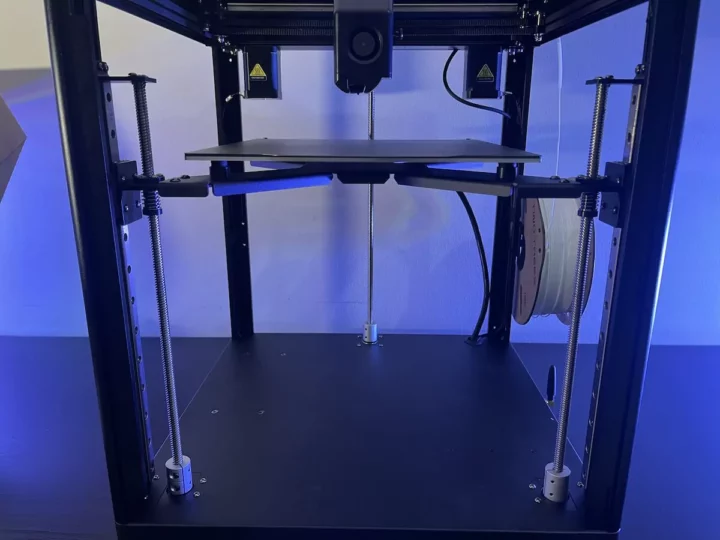

TwoTrees SK1 is an FDM 3D printer with a working area of 256 x 256 x 256 mm and a CoreXY system that can print 3 to 5 times faster than a typical 3D printer. The movements of a CoreXY 3D printer are achieved by moving two motors simultaneously. The TwoTrees SK1 CoreXY 3D printer can print at a maximum speed of 700 mm/s and features automatic Z-Tilt base leveling with a 36-point mesh bed. The print head uses a dual-gear direct extruder to feed the filament directly to the nozzle and the nozzle supports up to 300 degrees Celsius. The printer also comes preloaded with the popular Klipper firmware.

TwoTrees SK1 specifications

- Printing size – 256 x 256 x 256 mm

- Dimensions – 400 x 400 x 530 mm

- Printing speed – Up to 700mm/s

- Acceleration – Up to 20,000 mm/s2

- Nozzle temperature – Up to 300ºC

- Guide rail type – Bail screw guide rail

- Display – 4.3-inch touchscreen display

- Leveling – Z-Tilt included leveling

- Hotbed panel – PEI

- Optional support for Webcam (“AI camera”)

- Optional support for WiFi

- Klipper Firmware

TwoTress SK1 3D printer unboxing and assembly

The 3D printer ships with a range of accessories including tools such as a hex screwdriver, cutting pliers, a brass brush, a microSD card, filament, screw nuts, and so on.

Slide Rail and Belt System

The SK1 relies on a linear guide rail for every axis (X/Y/Z) that supports high-speed movement. And has been used in this 3D printer. The X and Y axis each feature a belt and two stepping motors to move quickly and accurately in their respective direction.

The Z-axis is controlled by three lead screws and motors.

TwoTress SK1 3D printer control screen

A 4.3-inch color touchscreen display is attached to the top of the printer.

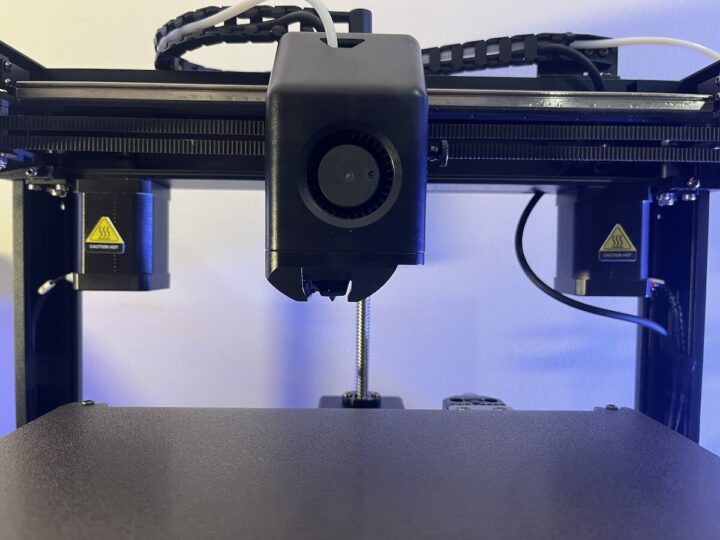

Extruder

A dual-gear direct extruder system feeds the filament directly to the 0.4mm nozzle which can be heated up to 300 degrees. One fan is used to cool the workpiece, and there’s also another high-powered ventilation fan.

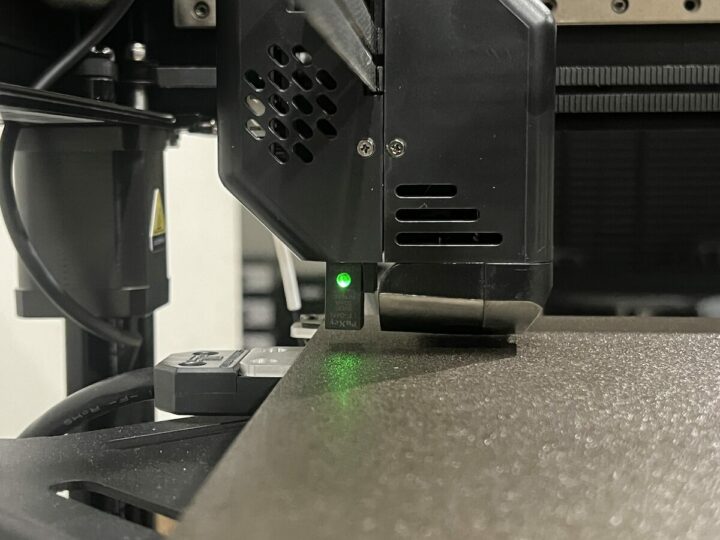

Inductive sensor on the SK1 3D printer

An inductive sensor is used to check the distance between the print head and the hotbed for printing accuracy and also prevents the print head from colliding with the plate.

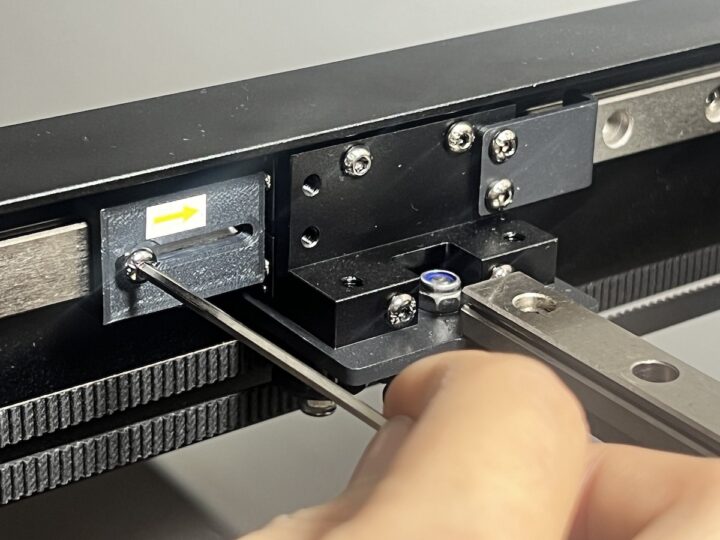

Unlocking the axis

In order to prevent damage during transportation, each axis of the 3D printer will be locked. So we need to remove the locks before using the machine. We show how to do it in the video embedded at the end of the review.

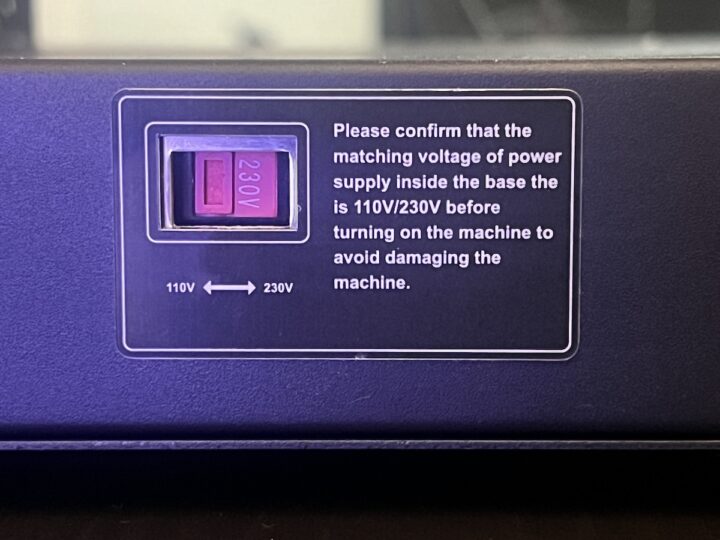

110V/230V voltage selection

Before turning on the machine for the first time, make sure the correct voltage is selected. There is a switch to adjust to 110V and 220V on the left side of the SK1 3D printer.

If the voltage is not set correctly, this happens (110V set when the mains are actually 230V):

The power supply blew up but it could be replaced by purchasing a MEANWELL LRS-350-24 power supply available on Amazon, Aliexpress, and other shops for under $30.

WiFi antenna installation

The WiFi antenna can easily be attached to the SMA connector on the side of the machine using the provided hex key.

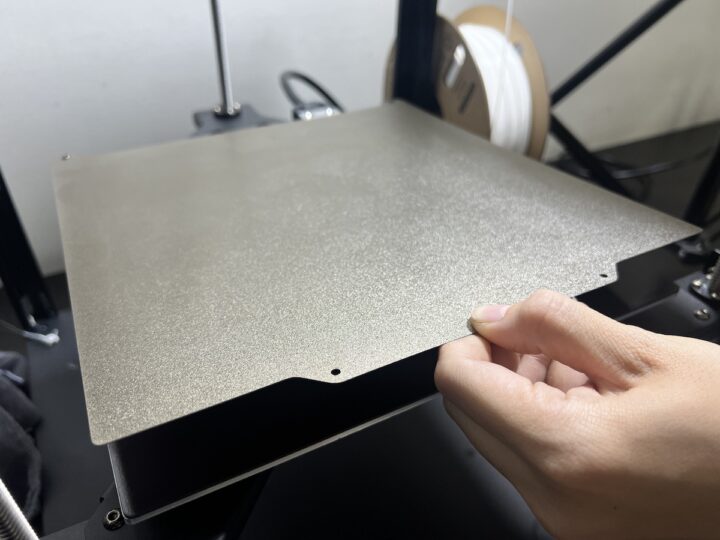

Printing plate

A PEI magnetic sheet will make sure the workpiece sticks firmly in place and does not fall off during printing. It can be used with a range of plastic materials and is suitable for printing with small surface areas or workpieces that require a smooth bottom surface. Once the print is done, the workpiece will come off easily without having to use tools to take it out.

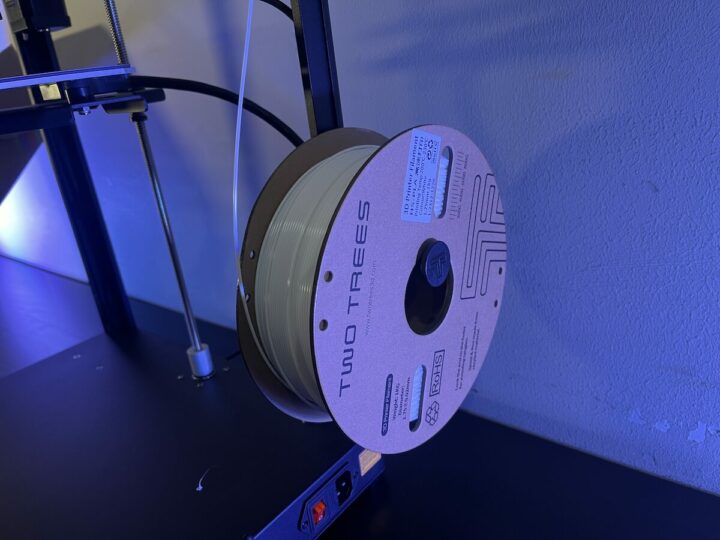

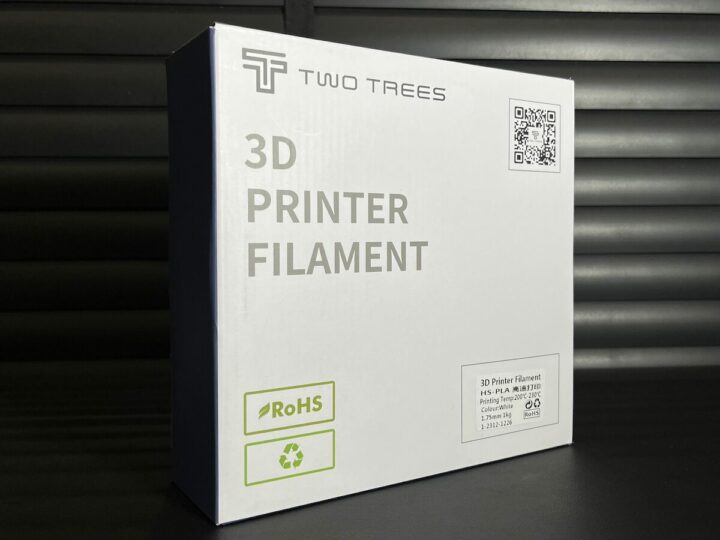

TwoTrees 3D printer filament

Our kit came with a 1kg HS-PLA filament spool from TwoTrees that is supposed to adhere better to the hotbed than standard PLA. The temperature used for printing is between 200 to 230°C and the diameter of the filament is 1.75 mm.

The filament spool can be installed in the steel hanger installed on the side of the SK1 3D printer and secured with two screws.

Preparing the TwoTrees SK1 CoreXY 3D printer

Ports

The mainboard comes with four ports as follows:

- Ethernet EJ45 jack

- USB 2.0 port is used to connect a flash Drive or a PC to send data to the printer

- USB 3.0 port is used to connect a flash Drive or a PC to send data to the printer.

- RJ11 connector to connect an additional display

TwoTress SK1 user interface

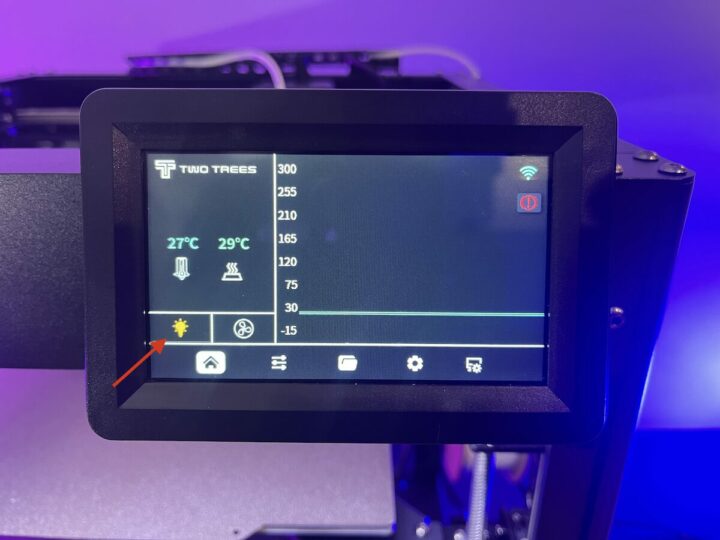

The Home page displays the temperature of the nozzle and hotbed, as well as the WiFi connection status.

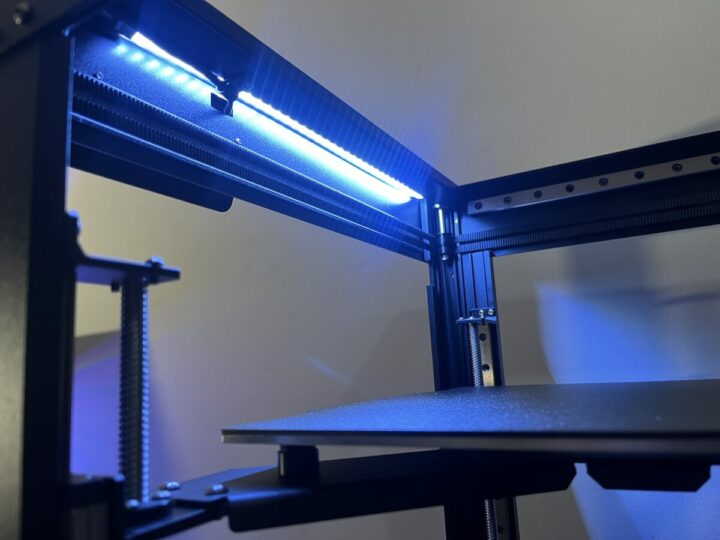

It can also be used to control the LED strip included with the printer…

… by tapping the light icon on the bottom left (White: off; yellow: on).

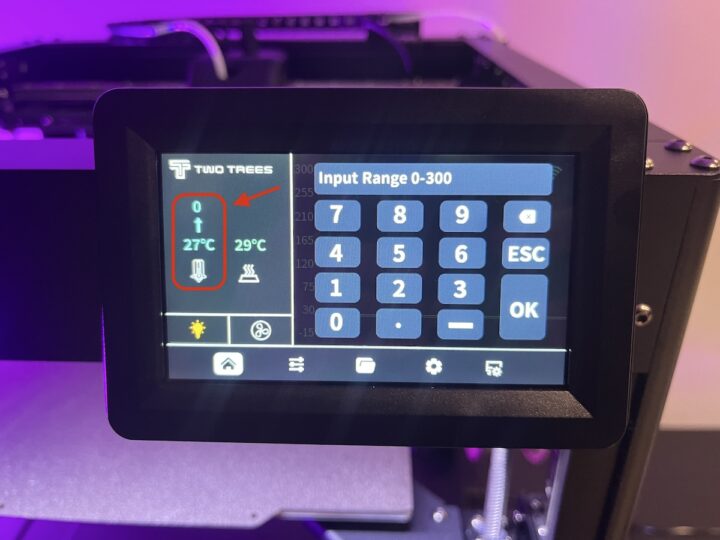

Tapping the nozzle icon allows the user to set the temperature of the nozzle by entering the required value between 0 and 300°C.

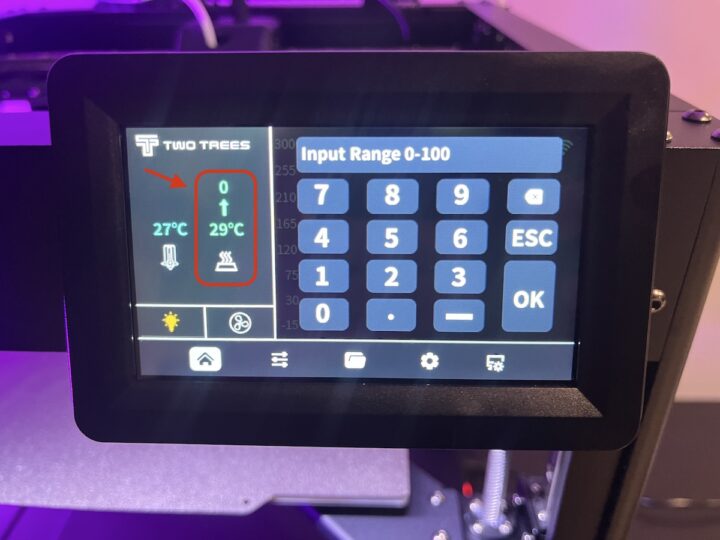

We can do the same for the heated bed between 0 and 100°C.

The second item in the bottom bar enters the Move/Temp mode allowing the user to manually control the motor X/Y/Z and set the default movement distance increment to be 1mm, 10mm, or 30mm. It’s also possible to adjust the temperature and/or stop all motors in this window.

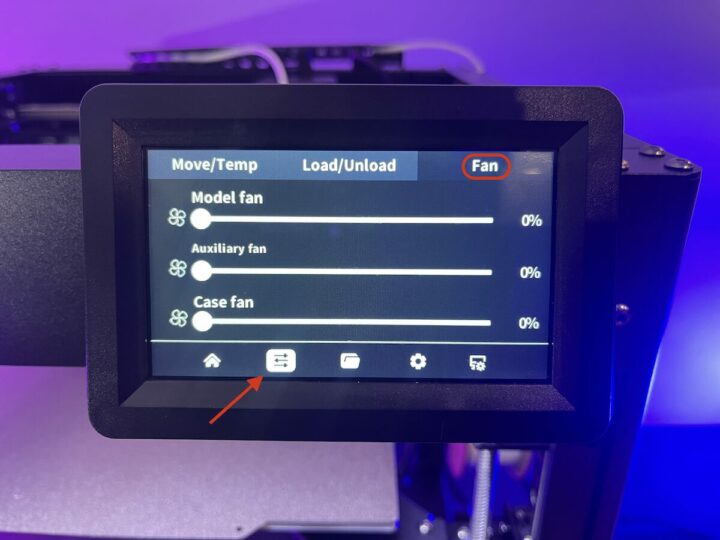

The fan mode provides options to independently control the model, auxiliary, and case fans from 0% (off) to 100% (full speed).

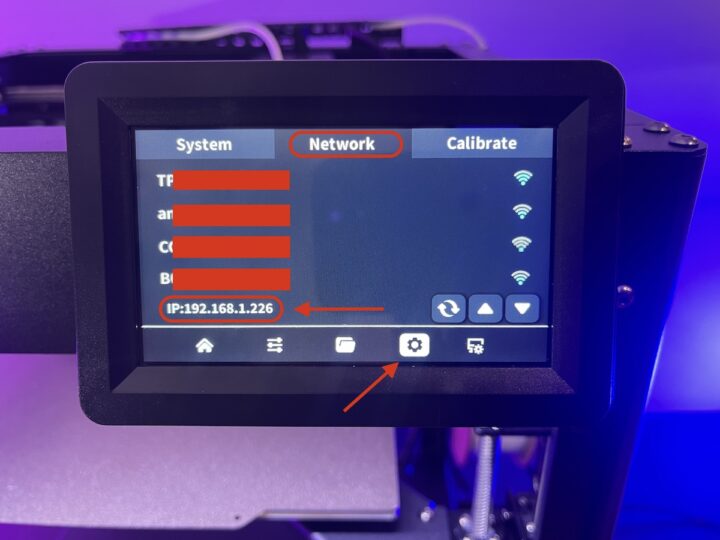

Tapping the gear icon in the bottom bar enters the System menu to set screen brightness, automatically off the display after a period of time, select the language, and perform a self-test.

This menu can also be used to configure the network (WiFi or Ethernet) to access the 3D printer via the web-based user interface provided by Klipper.

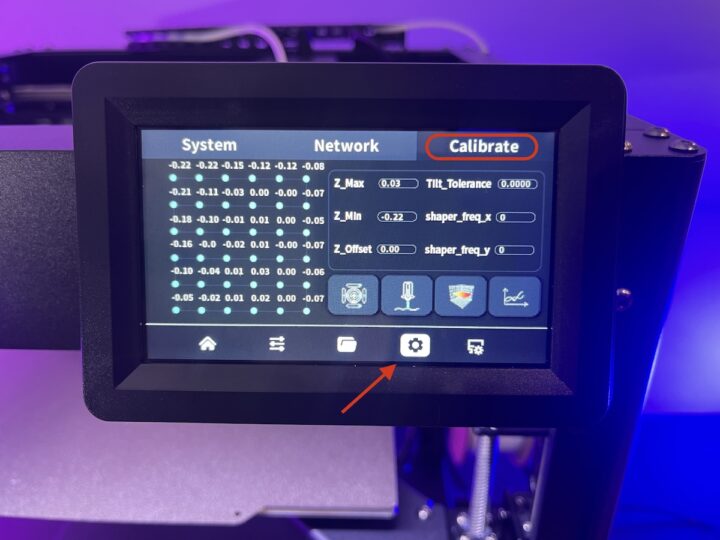

Leveling the bed of the SK1 CoreXY 3D printer

The same menu can be used to level the printing bed as the SK1 3D printer has a function for automatically calculating the tilt of the print bed by probing 36 points on the bed and ensuring the plate as perfectly horizontal as possible even though the chassis of the printer may not be. The calibration step is showcased in the video at the end of this article.

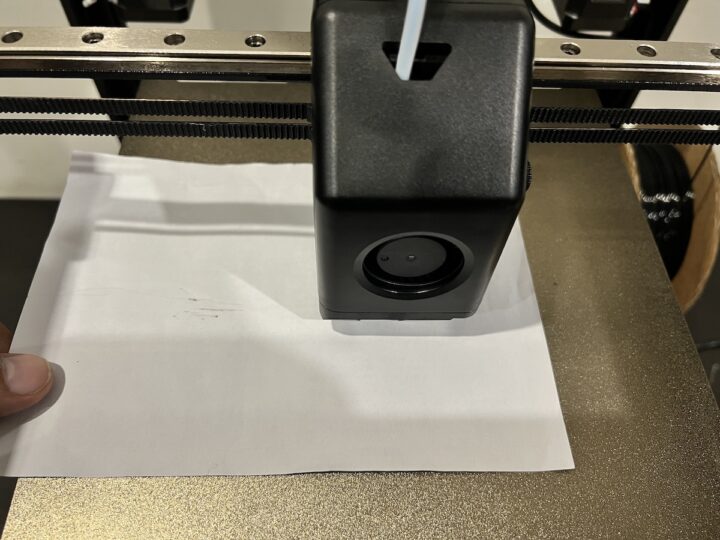

Printing head height calibration

The height of the printing head of the SK1 3D printer also needs to be calibrated. We can do this manually by adjusting the height in the user interface and once we get the correct value we can tap on the OK button.

How do we determine the correct Z value? By using an A4 sheet of paper as we did in our Creality Ender-3 S1 Pro 3D printer review. We must adjust the height of the nozzle by making sure it touches the paper but still allows us to move it with some friction.

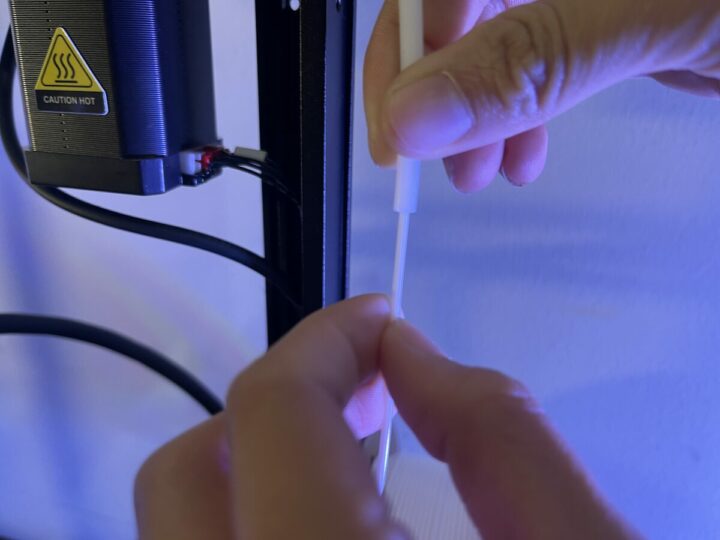

Loading/unloading the filament

We need to insert the filament into the nylon tube that comes with the 3D printer and push it in as far as it will go.

Once this is done, we can go to the Load/Unload section of the user interface and tap on the “Load” button with the desired temperature. The 3D printer will then handle this for us automatically.

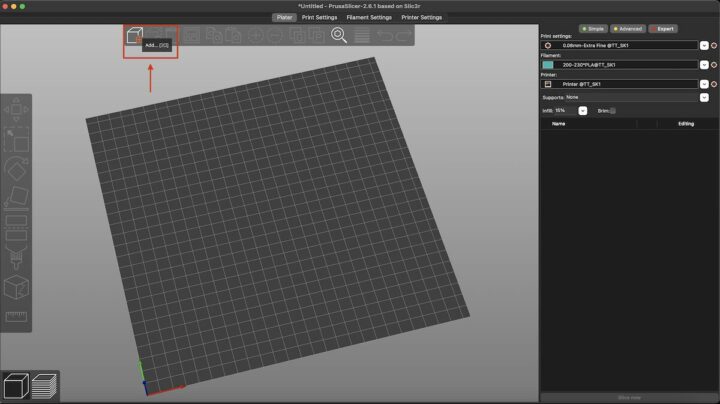

Using the PuraSlicer program with the TwoTress SK1 3D printer

PuraSlider installation and SK1 configuration

3D models must be converted into G-Code before printing. This is done by a slicer program, and we will use the PrusaSlicer program (version provided by TwoTrees) in this review.

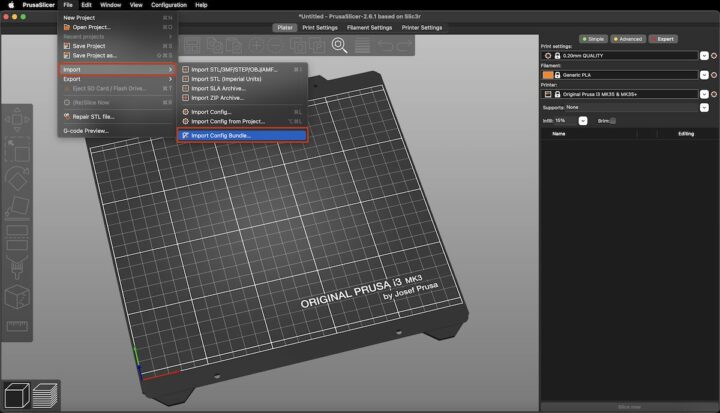

The first thing to do is to import a configuration file for the 3D printer through File >>> Import >>> Import Config Bundle in the top menu.

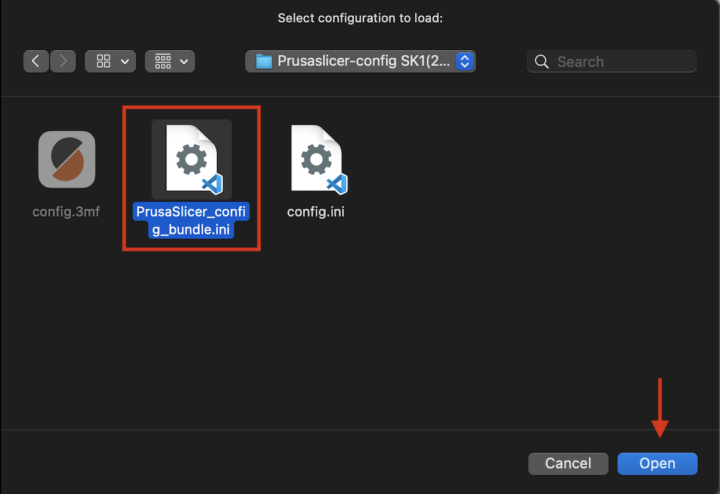

Select the file named PrusaSlicer_config_bundle.ini then click “Open”. You’ll find the file on the microSD card provided with the 3D printer or on MediaFire.

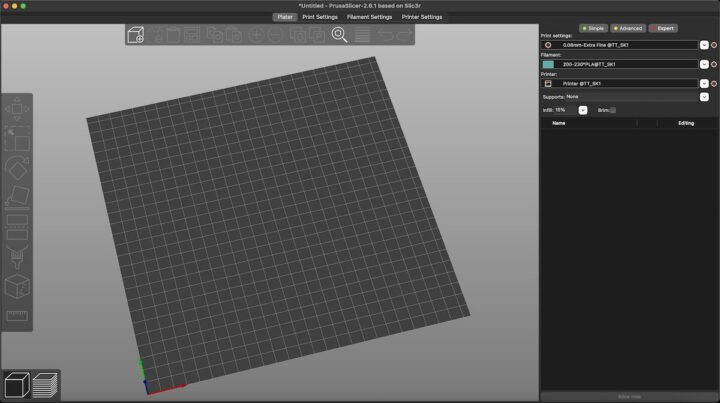

The SK1 3D printer is successfully configured in the PrusaSlicer program.

Converting 3D files to G-Code

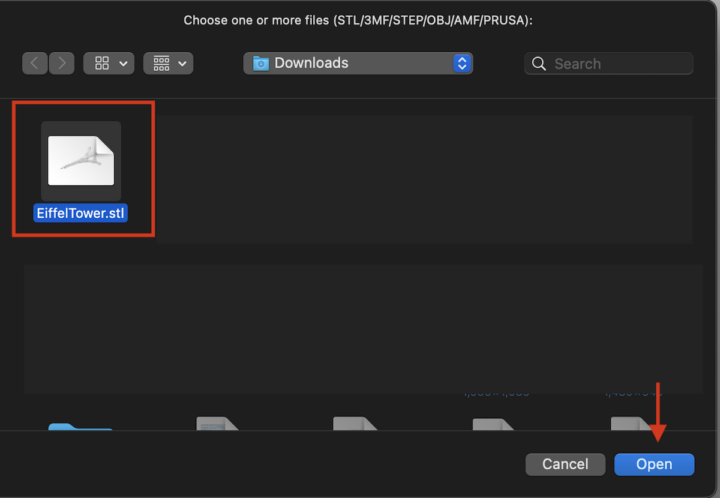

We can now import a 3D model file by clicking on the Add icon as shown in the screenshot below.

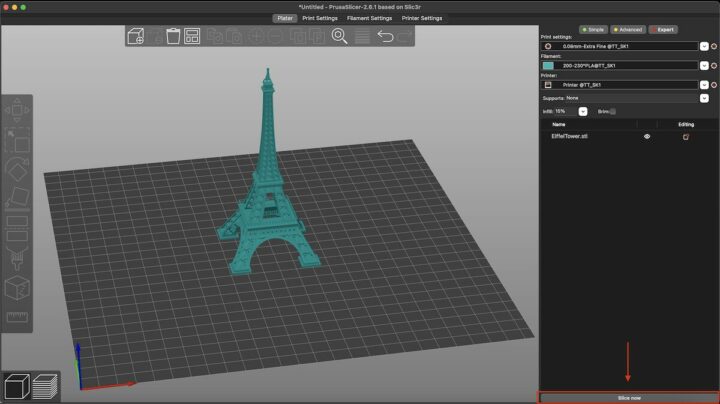

Select the 3D model file with extension STL, 3MF, STEP, OBJ, AMF, or PRUSA, then click on “Open”. We selected “EiffelTower.stl” for our test.

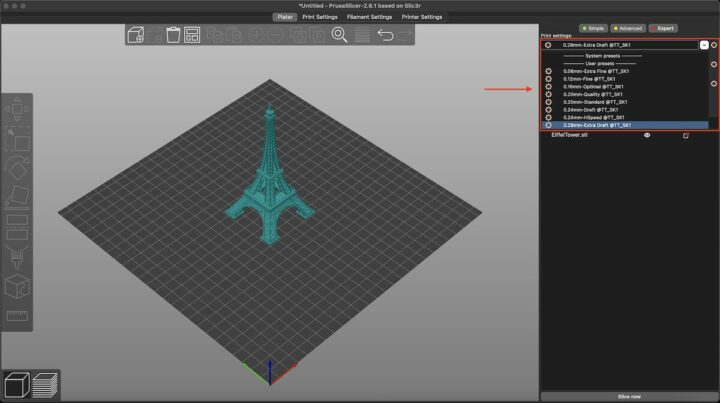

PrusaSlicer will then display a 3D representation of the model on the printing plate.

We can set the print resolution to be 0.08, 0.12, 0.16, 0.20, 0.24, or 0.28mm which will impact the quality of the sample and printing time.

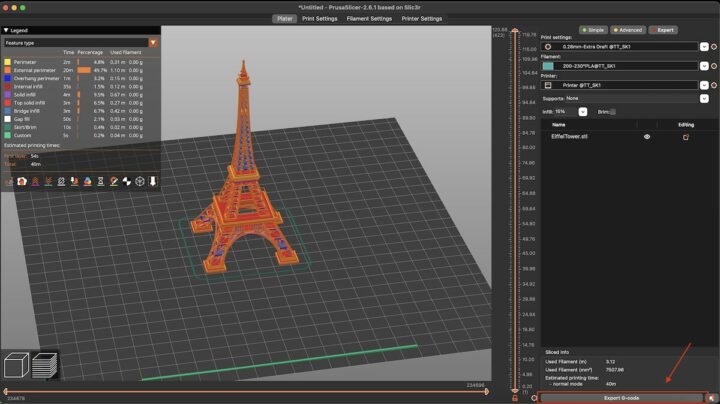

Once this is done, we can click on “Slice now” to begin processing the file.

The program will also calculate the printing time and amount of material required. We can then download the G-Code file to a computer or put it in a USB flash Drive by clicking on “Export G-Code” to complete the file conversion process.

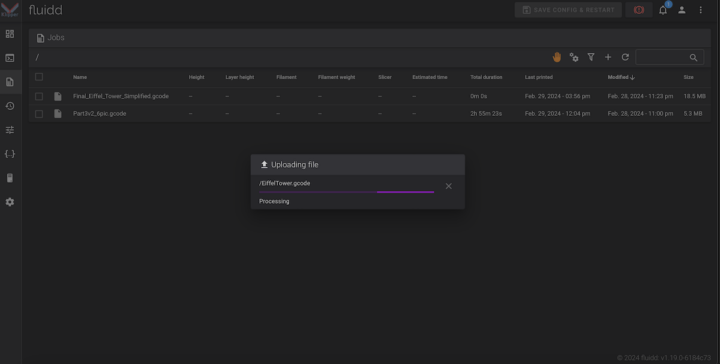

Klipper firmware web interface (Fluidd)

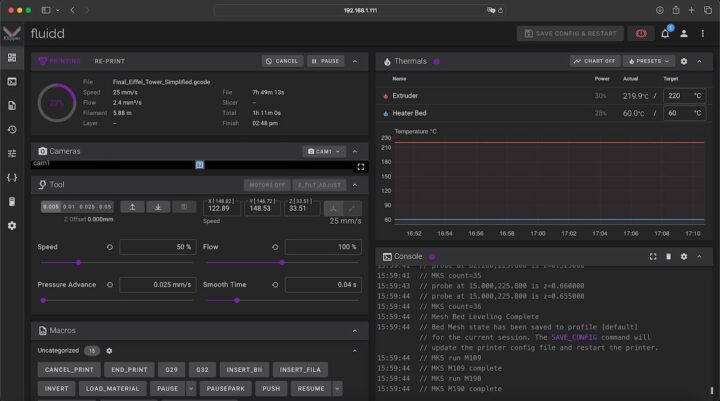

We can log in to the Klipper dashboard (Fluidd) after connecting the 3D printer to a WiFi network and using the IP address shown on the display.

Uploading G-Code to the SK1 3D printer over WiFi (or Ethernet).

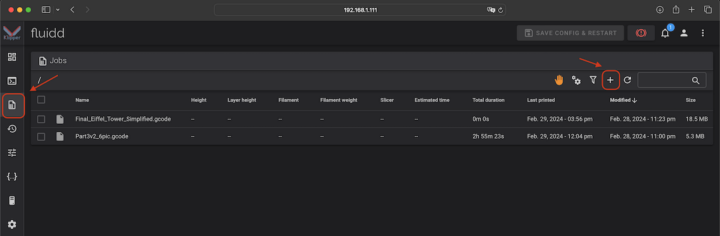

Let’s go to the Jobs section by clicking on the relevant icon on the left banner and then clicking on the + sign to add a new job.

Select the .gcode file we have just exported (EiffelTower.gcode), then click on the “Upload” button.

The file will be uploaded to the 3D printer, and after that, you can select it and print the workpiece.

Selecting a G-Code file from a microSD card or USB drive

Alternatively, the TwoTress SK1 3D printer can also print 3D parts from a microSD card or a USB flash drive through the touchscreen display by going to the USB mode of the user interface.

Printing samples with the TwoTrees SK1 CoreXY 3D printer

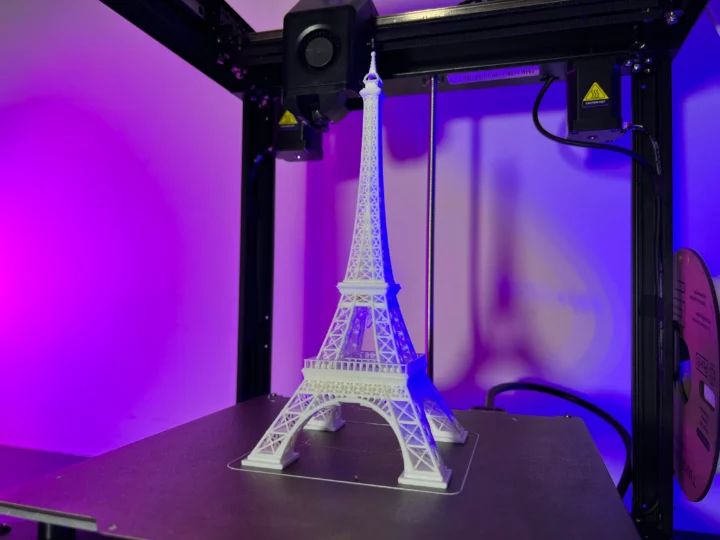

Eiffel Tower model

Material: PLA; layer: 0.28 mm; infill: 15%; speed: 200 mm/s; travel: 500 mm/s

Print time: 3 hours 10 minutes

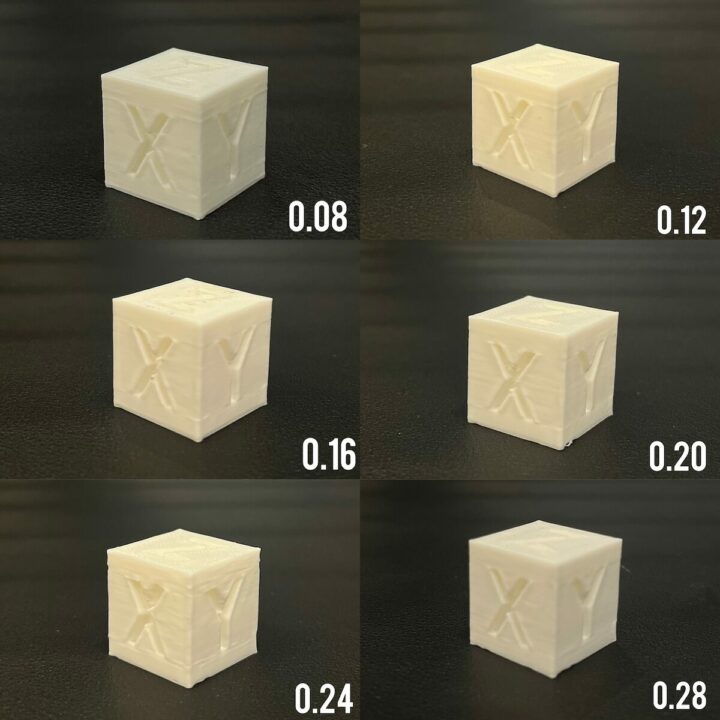

Calibration cube with different resolutions

An XYZ 20mm calibration cube was printed with the following parameters – material: PLA; layer: 0.08 to 0.28 mm; infill: 20%; speed: 200 mm/s; travel: 700 mm/s

A visual inspection does not reveal any obvious differences between different layer thicknesses.

Benchy model printed at maximum speed

We also printed a Benchy at maximum speed (700mm/s).

Material: PLA; layer: 0.20 mm; infill: 25%; speed: 700 mm/s; travel: 700 mm/s

Print time: 18 minutes.

The resulting print is not too bad and much faster than Karl’s speed printing experiment with the Longer LK5 Pro 3D printer where he could print the Benchy in 37 minutes after some optimization and some “cheating” (0.3mm thickness), while his 0.2mm print would take well over 45 minutes. So CoreXY 3D printers clearly have the upper hand when it comes to speed printing without sacrificing the quality too much if at all.

Flexible dragon model

Material: PLA; layer: 0.28 mm; infill: 15%; speed: 300 mm/s; travel: 700 mm/s

Print time: 3 hours 32 minutes.

Lion model

Material: PLA; layer: 0.20 mm; infill: 15%; speed: 400 mm/s; travel: 700 mm/s

Print time: 2 hours 11 minutes

Video review of the TwoTrees SK1 CoreXY 3D printer

Conclusion

The TwoTrees SK1 3D printer works well and enables impressive speeds thanks to its CoreXY design that enables speeds up to 700mms that are several times faster than traditional FDM 3D printer, but for instance, a Benchy could be printed in 18 minutes using a 0.2mm layer.

The Z-Tilt auto-calibration feature is convenient to use and lowers the risk of issues during printing. The SK1 3D printer has a good build quality with a solid structure that supports the movement of the X/Y axis. The Klipper firmware also helps with delivering good quality prints and a familiar user interface enabling the upload of G-Code files over WiFi. The 3D printer is suitable for small businesses, enthusiasts, or even the classroom.

We would like to thank TwoTrees for sending us the SK1 CoreXY 3D printer for review. The 3D printer can be purchased for $499 on TwoTrees’ online store, on Aliexpress, and they also have an Amazon store, but the printer is not listed there just yet.

CNXSoft: This article is a translation – with some additional insights – of the review on CNX Software Thailand by Kajornsak Janjam, edited by Suthinee Kerdkaew.

Jean-Luc started CNX Software in 2010 as a part-time endeavor, before quitting his job as a software engineering manager, and starting to write daily news, and reviews full time later in 2011.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress