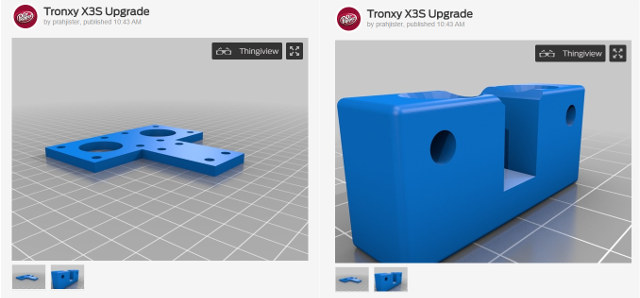

Karl here. I have had the Tronxy X3S 3D printer for a while now. It prints well but as I mentioned in previous articles I had to level for every print. Actually near the end I would just overpower the stepper motors while the skirt was printing and level. Leveling front to back was not affected. Only the z height. So this worked but it was frustrating. Before that I tried several different things to mitigate. I thought maybe the endstop for Z homing was inconsistent and replaced it. I tried heating the bed for extended period of time thinking that maybe some thermal expansion. Didn’t help. I finally did a major change to the X carriage with success. I even moved the printer to our local library and the bed stayed leveled for a demo. I call this a success, and will show how I did it. Inspiration for […]

Tronxy X3S 3D Printer Review – Part 2: Upgraded Heatbed and RAMPS Board

Karl here. So the bed I mentioned in the first part of Tronxy X3S review is not very good. It took about 10-11 minutes to heat up to 60 deg Celsius. I also mentioned I was going to upgrade the board to a RAMPS board. Today we are going to look at both these upgrades. New Heated Bed I can take no credit for this one but I wanted to pass this along. Folger tech sells a 12v 280w heated bed stick on pad. I picked this up for $20, but is now $22. In order to do this upgrade you will need a MOSFET, 12V/30A power supply, and of course the pad above. Super easy installation. Remove the bed and stick on the self adhesive pad centered. Replace the power supply with new one. Should be self explanatory. In order to power this bed a MOSFET is needed. A […]

Tronxy X3S 3D Printer Review – Part 1: Build and First Prints

Karl here with part 1 of Tronxy X3S build. It is another large volume printer to fully assemble on your own. Taking between 8-10 hours to put together. I have high hopes for this printer. Key things I like: metal frame, dual X, large build volume. Just from looking at it I don’t like the fact that it has no parts cooler but is easy to remedy. Tronxy X3S Specifications Let’s look at some specs. 300 x 300 x 400 mm hot bed (Actually get 330x330x400 build volume) Hot bed temperature: 40 – 110 Deg.C Nozzle temperature: 170-275 Degree Marlin 1.1.5 Frame material: Aluminum Extrusion I have not taken the hotend apart yet so not sure about the nozzle temperature going over 245°C. I will take it apart for the next part. If you are not familiar you don’t want to get lined nozzles above 245°C, or the lining starts […]