We covered Xassette-Asterisk open source-hardware Allwinner D1s RISC-V Linux SBC last October. But it will most likely never be mass-manufactured since SdtElectronics, the designer, has no resources and time for production. So I thought I should give it a try, and I managed to get 10 boards manufactured and assembled.

Time for a little disclaimer. While the post is not sponsored in the sense I did not get paid for it, NextPCB agreed to cover all costs, aka sponsor, and manufacture ten boards. Today, I’ll report my experience manufacturing an open-source hardware board, but I had no time to check whether any of the boards worked.

Manufacturing timeline

Since I did not want to go through the whole process of ordering the PCB, purchasing the components, and soldering each board individually, I opted for NextPCB’s PCB manufacturing and assembly services. Here’s the detailed timeline:

- November 9 – Ordered 10 boards on NextPCB using Gerber files and BoM on Github.

- November 10

- Received an (automatic?) email saying my order failed verification

- Received an email from my assigned support contact (Betty) telling me drilling data was missing, and asking for further clarification about some items in the BoM.

- Sent drill data after generating it from KiCAD using those instructions. Asked SdtElectronics to help me with the BoM issue.

- November 11

- Got a reply from SdtElectronics and sent the updated BoM with clarifications

- NextPCB still had some small issues with the BoM (LED color, Allwinner D1s purchase link, etc…)

- Since some of the components are optional, I could handle that myself without bothering SdtElectronics, and provided instructions

- Clarification about the order (9 fully assembled board, 1 bare PCB) as I made some mistakes while ordering online.

- November 12 – More questions about BoM, mostly asking about confirmation about connectors, Crystal part, etc… But I missed that email and did not reply…

- November 16

- Asking me again about BoM, and this time I did reply.

- Received an email saying my order had been verified successfully

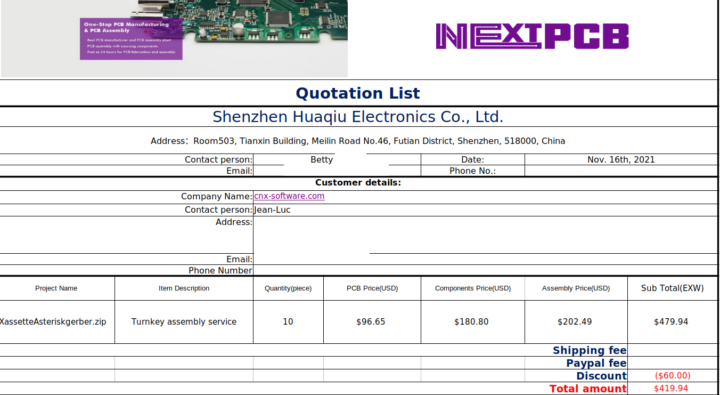

- Received a quotation (To this point, I don’t think the person in charge knew I would not pay for it…)

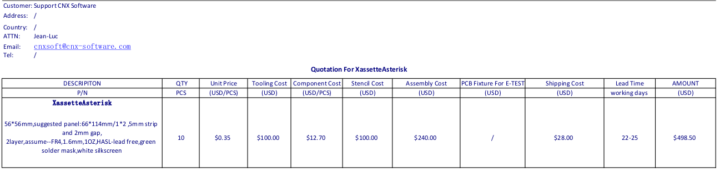

$419.94 in total before shipping, or about $41.90 per board. If that board was mass-manufactured it would cost closer to $10 per unit, and that’s why companies are doing crowdfunding… - Sometimes companies contact CNX Software before reading the “About” page, and another company asked me if I had any PCBs to manufacture, so I received a quotation from another company (Note that’s for 10 fully assembled boards, instead of 9+1).

$498.20 including shipping. That’s quite similar to the NextPCB quotation, so $40-$50 per assembled board should be the expected cost for such a small order. I did not manage to get free samples from this manufacturer…

- November 18

- Received an email from Betty asking if I checked the quotation

- I replied I was not going to pay! 😮

- November 19

- Received an email saying the payment was successful!

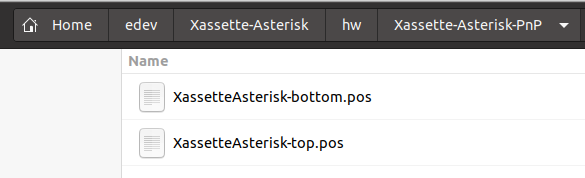

- Received an “urgent” email telling me I had selected the “castellated holes” process when uploading the PCB files (oops, my bad), and was asked for the pick and place file for assembly. I followed some instructions on Seeed Studio to generate the file from KiCAD.

- November 22, 2021

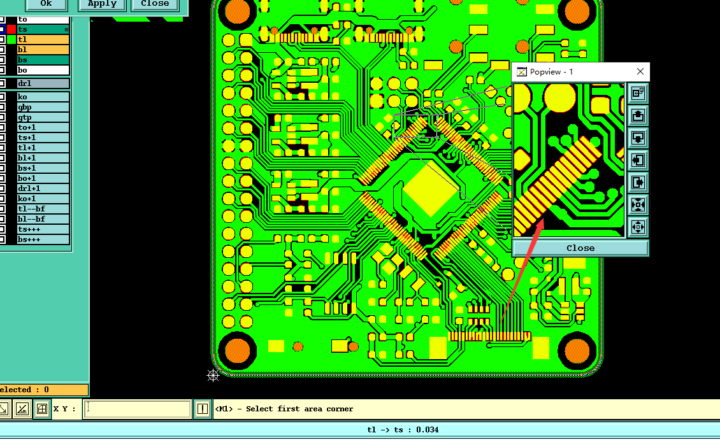

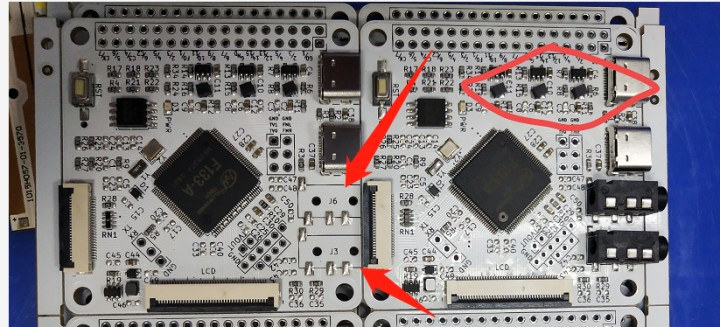

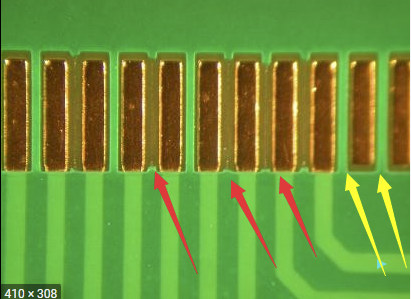

- Received Working Gerber (also in PDF format) for verification. I was also told they made some changes: ” for the position by arrow indicated, it can not be made as solder mask bridge, so our engineer suggests that help you connect the pads together(whole opening), is ok for you?”

- I contacted SdtElectronics again to check the Gerber and get feedback about the “solder mask bridge” since I did not clearly understand it:

I assume gaps between pads at some positions are too small to make solder mask upon. As long as the manufacturer will take care of the soldering that would not be a problem, otherwise the absence of solder mask may cause difficulty to soldering (by hand).

- I also gave the go-ahead with production

- Received Working Gerber (also in PDF format) for verification. I was also told they made some changes: ” for the position by arrow indicated, it can not be made as solder mask bridge, so our engineer suggests that help you connect the pads together(whole opening), is ok for you?”

- November 23

- Received an email saying fabrication will start, that components are sourced and everything is going, and not to worry… I also got a further explanation about the solder mask bridge “issue”.

Please check the picture, the position by yellow arrow indicated is made as solder mask bridge, the position by red arrow indicated is made as “connect the pads together”, also you mean “no solder mask”.

- Received an email saying fabrication will start, that components are sourced and everything is going, and not to worry… I also got a further explanation about the solder mask bridge “issue”.

- November 30 – Email update informing me the PCB fabrication had been finished, the components were in transit, and should be received next week. Plus details about the next steps:

- Count the components first, compare the pads on board.

- Start the assembly production if no any issues need to confirm.

- Send you the sample board photos to confirm.

- Continue to the rest production and ship out the boards soon.

- December 7 – Urgent email asking me for the Pick and place file. I thought I had already sent those on November 19, but sent them again.

- December 10

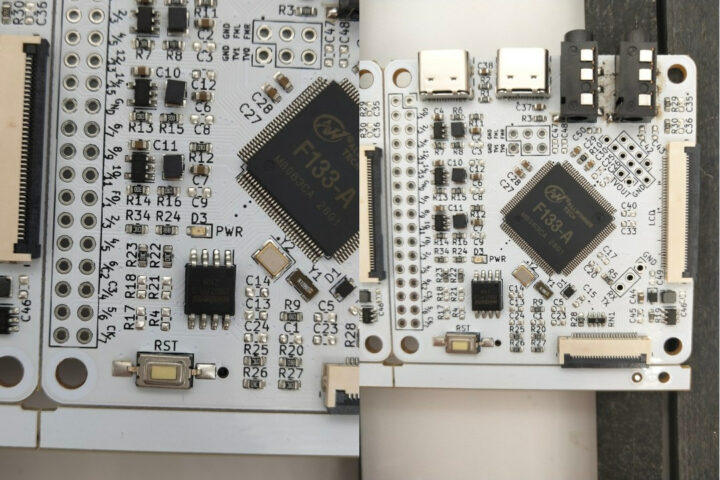

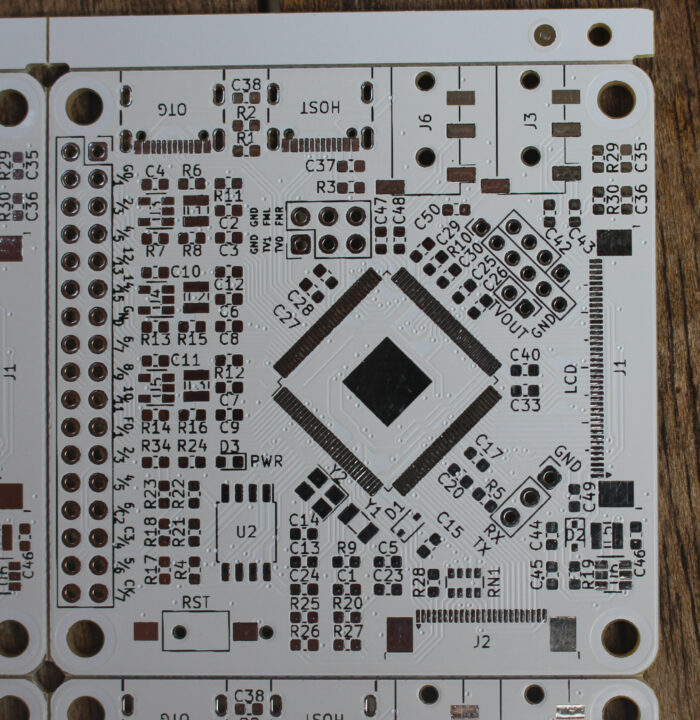

- Received photos of the first sample for checking. I was also informed about some problems with the design:

… the parts circled by red line, the pads are a little smaller, they may be pulled off in Reflow soldering process, we will help you repair them manually before shipment, but also please improve your this design in future.

Most of the capacitors are not soldered because they fell off after reflow soldering due to the small pads. For sample quantities, the manufacturer can rework the board and manually fix the issues, but the design should be modified for mass production, and I was told they would do so. - Apart from that, the board looked fine to me, but SdtElectronics kindly provided feedback again:

I did find some issues from the pics you uploaded. R21, R18 and R17,

R14R4 are jumpers for boot media selection and they must NOT be soldered simultaneously. I have mentioned this in notes of README, as well as the commented BOM list. Should a card was used as the only boot media, all these 4 resistors can be removed. Same reason for R33 and R32. They are jumpers and only one of them should be soldered (R32 for most LCD panels).About the skew components (3 inductors in your pics), I have also experienced this when soldering by hot plate (they were right, melted solder paste pulled components off) and I have to adjust them manually. This would not be a problem as long as two pads of the inductor are not shorted.

- Received photos of the first sample for checking. I was also informed about some problems with the design:

- December 13

- Sent feedback to NextPCB

- Received photos of updated PCB

I focused on the removal of R4, R18, R17, R21, and R33 (on the back, not visible on photo above) and that was fine to me. The capacitors were still not soldered, and I thought this would be done manually later (rookie mistake! as we’ll see later), so I gave the go-ahead to complete production.

- December 17

- December 22 – Received the board in Thailand

- December 23 evening – Boards in CNXSoft hands!

So far, I was quite pleased with the way it was handled. It took around 6 weeks from order to delivery. Another person also built the board by himself and apparently did so in about two weeks.

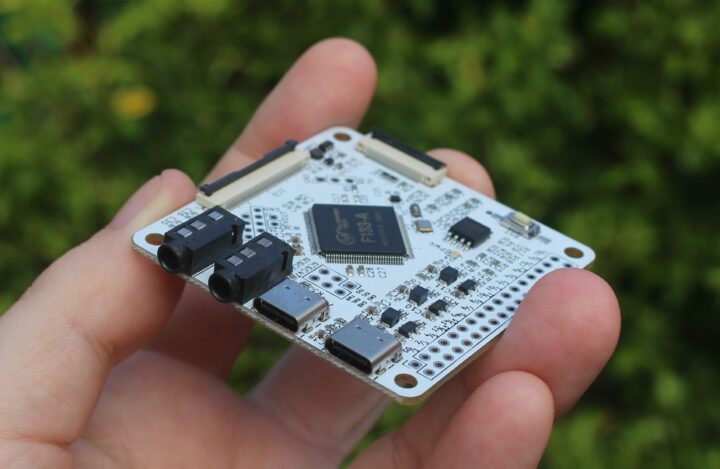

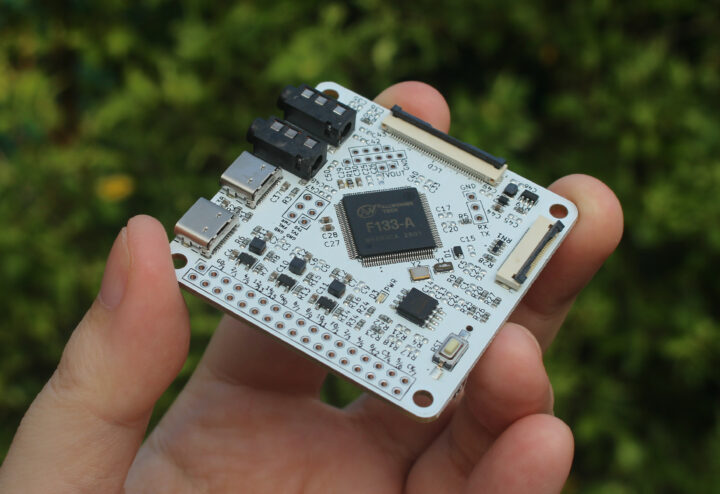

Checking out Xassette-Asterisk boards

So let’s see what we’ve got…

I only expected 9 assembled and one non-assembled board, but I got a bit more than expected including one bag with “garbage” as jokingly described by my girlfriend. That bag contains unused components. That’s because suppliers won’t just sell bags with 9 components (except for the processor see black box), and will ship the components in varying quantities of 10, 30, 40, or even 100 pieces as illustrated by the photo below.

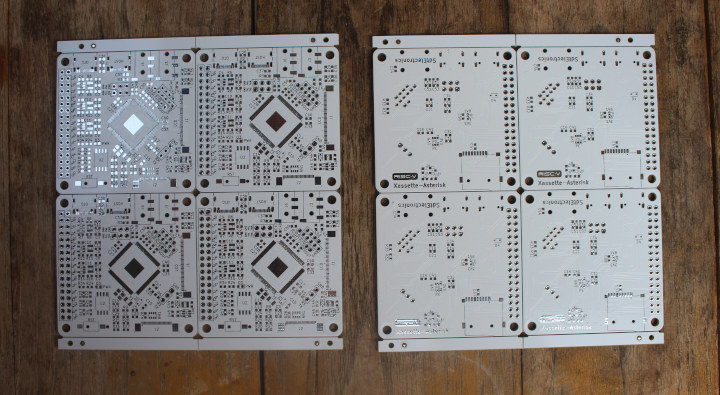

Time to have a look at the bare PCBs. I received two panels of four boards each.

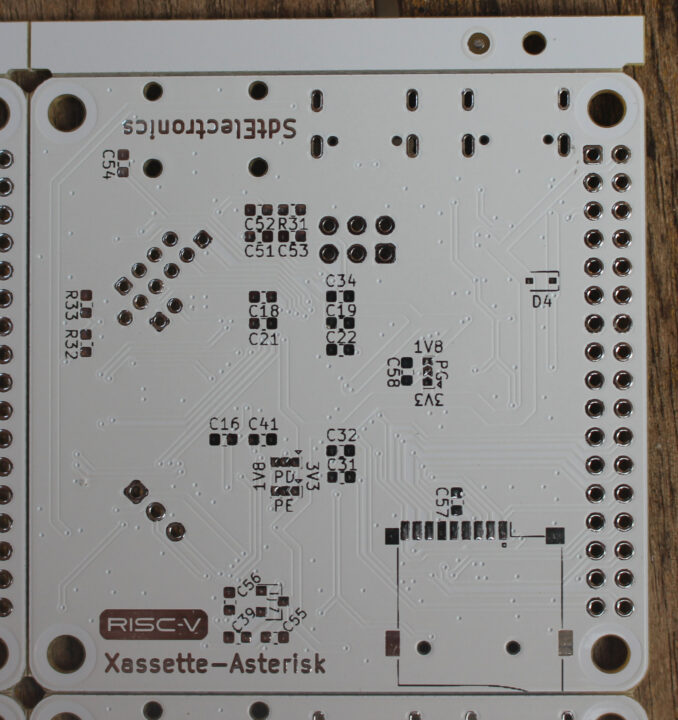

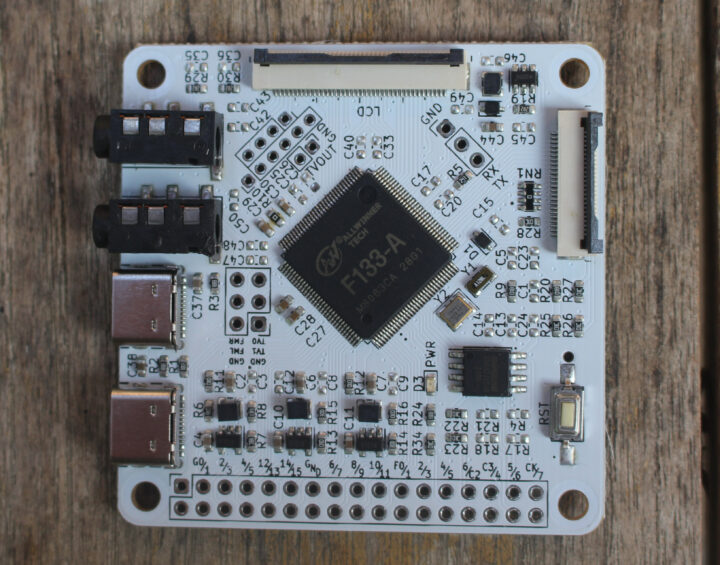

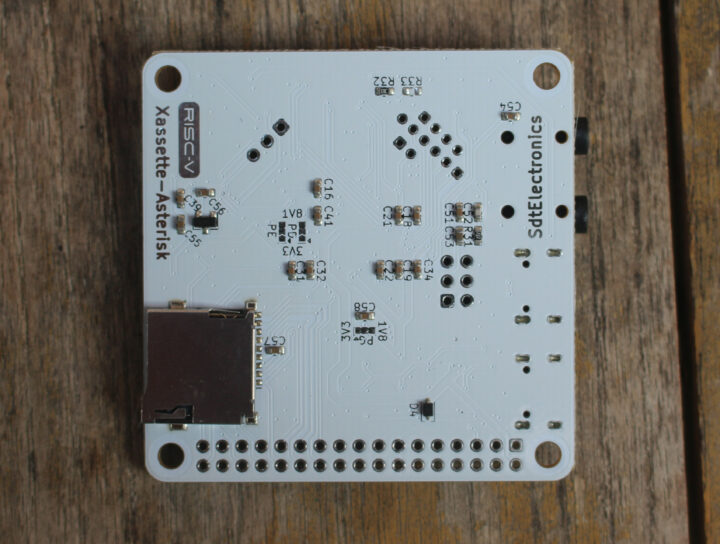

Higher resolution shots…

and now for the fully assembled board…

and in the sun…

It all looks good to me except the capacitors that fell off during reflow soldering were not soldered manually, so I’d have some work to do before testing the board.

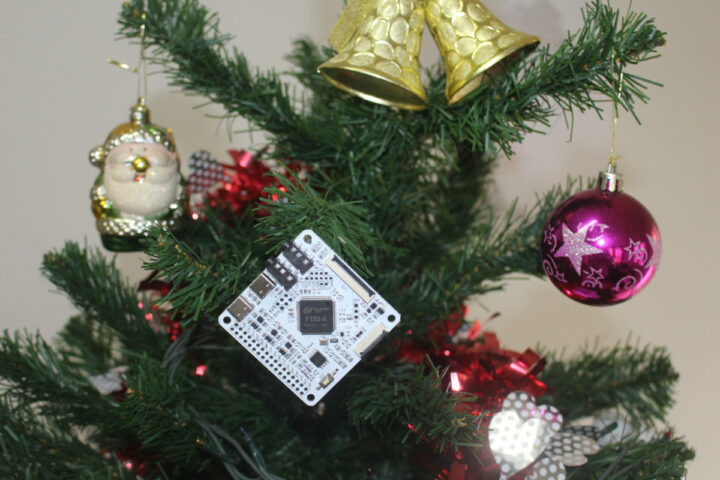

This will take a while since I won’t have access to a soldering iron for several weeks. If the boards don’t end up working, they make great Christmas tree ornaments!

If you’d just like to play with an Allwinner D1s or F133-A, I’d recommend waiting for the MangoPi MQ board that should start selling very soon. But if you like a challenge with some soldering and board bring up, I’m giving away 6 pieces of the assembled boards, [Update: all boards have been taken] and the two bare PCB panels. I’d just ask $7 for registered mail (count 2 to 4 weeks). Only one board or panel per person, and I’ll include some components bag as well (after keeping some capacitors for myself). Since I don’t expect many takers for a board that may or may not work, you can just reach out through the contact form if you are interested.

Jean-Luc started CNX Software in 2010 as a part-time endeavor, before quitting his job as a software engineering manager, and starting to write daily news, and reviews full time later in 2011.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress. We also use affiliate links in articles to earn commissions if you make a purchase after clicking on those links.

Looks good, crisp as freshly baked cookies. Now waiting for review on software side.

Thanks, very useful

Very nice Post!!

Merry Xmas.

More than being about the AllWinner chip, I think this set of posts has been helpful in sharing with people an understanding of how difficult it is to get a board produced. Not everyone has been a part of such a process and doesn’t, therefore, appreciate the complexity of such a project. Little details can hang things up for weeks at a time. Communication back and forth can add several unexpected slips in the schedule.

I’m ‘lucky’ in that I got exposed to this in my first job out of college, so later when I was involved with a few hobbiest designs, I was prepared for what I would run into. A half dozen projects later and I still know to prepare for the unexpected if/when I ever do another board.

So, thank you for helping to educate more people in all the difficulties you will face when approaching a project like this. And, everyone, keep in mind that this was with an already designed board. Even getting to that point is quite a project!

Happy holidays!

Author of this project here. I really appreciate this comprehensive guide on batch manufacturing, which I haven’t got resources to do it myself. May I link to this post in the README page in my project? By the way I have updated the hardware design to support WiFi modules, thus the image in the Github repository looks different from those in this page.

Of course, you can link back to this post. Thanks for your work and help for the small batch manufacturing.

Thanks for all insight into this open source knowledge support. Maybe you can give some words about how much time is to invest on this level of SBC hardware design (about 122 components/parts, with capacitors ~60 and resistors ~30) and SoC implementation on ~GHz (hi-speed demands for traces). Do you think about changing towards commercial design software or is open source a more appropriate way for world wide interaction and development support? Do you think that with drilling holes there’s risk of changing impedance/signal timings on one or the other point on the pcb?

That’s a lot of questions lol, but I am glad that someone has interest in the development of such projects.

About the time investment, it will vary significantly according to the experience of the designer and the design itself. I am an amateur with limited time can be spent on these projects, and it took me a couple of weeks to start from design to finfish the soldering and test. D1s is a nice chip with in-package RAM and thoughtful arrangement of pins, thus it is rather simple for PCB layout. On the other hand, it is a new product with little documentation and support, so I have to work out lots of stuffs on my own.

About EDA software, I’d say for KiCAD it still has a long way to go. I designed this board with KiCAD 5.1.6, and its feature gap between commercial software made some operations rather painful. But I stick to KiCAD for OSHW projects without hesitation, since a format available to everyone is important for open-source. I am really excited to see the KiCAD 6 which was released recently has significant improvements in various aspects.

For vias, they could be deleterious for high-speed signals, but fortunately there isn’t any on this board. Generally, more attention should be paid on signals with requirement to impedance and clock alignment, and this would be a sophisticated topic that won’t fit in a short comment.

Thanks again for Your explanations.

It also gives an idea what SBC’s with external ram, pcie, usb 3.x, networking on >=2.5Gbps and maybe 10 or more pcb layers are in terms of progress within electronics for computing devices (with customers mostly not being aware of).

Very cool. Thank you for going through the process in detail. One often reads “anyone can order custom PCB!” but rarely any detail on “yes, but exactly HOW…”

interesting to see how the manufacturer was very helpful with testing and identifying errors, but of course could not know much about your design goal or your own post manufacturing capabilities either, so not clear if they could catch every potential problem. Tell us how board works! 😀

Board in hana. Thank you, Jean-Luc!

Great! I’ve yet to try mine. By the way, some capacitors may not be needed. Check out line 5 in the BoM @ https://github.com/SdtElectronics/Xassette-Asterisk/files/7519220/T-9pcs-BOM.1.-Component.revised.xlsx

I completely forgot about that when I wrote the post.

That’s where I am now. I cataloged the ‘missing’ pieces and I’m trying to categorize them between ‘needed’ and ‘used to select things’. I’m still stuck on some of the voltage selection jumpers, but I think those are for interfaces I’m not using and I think I can safely leave them for now.

Board in São Paulo, Brazil

Thank you Jean-Luc!!!

Cool! Let’s hope it works.

The board arrived this week to Spain.

Thanks Jean-Luc!!!

Good that you got it, but I did not expect it to take so long.

It is for sale on Aliexpress

https://fave.co/3rL3iLz

Lol! They copied the entire article and title from CNX Software. At least they kept the backlinks…

Yeah I noticed the style look familiar 😆

Thinking on, since they used your article, you should asked for a couple of boards to do a CNX Software site giveaway ! 🤔

I think I saw them copy other pages. Once I tried to issue a DMCA takedown to the Aliexpress page copying my full article, but Google says they can’t do it for third-party content which seems BS to me.

Only the copyright holder can ask for DCMA takedown. But you would have to ask Aliexpress to remove the page, it is not being hosted in Google. As for removing it from search, that probably needs a court order.

Yes, it was to remove it from Google Search. I can do it for other websites, but not Aliexpress for the following reason:

Google typically has no problem removing copied content from other (smaller) websites.

Aliexpress has a process to remove content but only for a registered trademark. So Aliexpress sellers can copy content as much as they want, and there’s nothing that can be done against it.