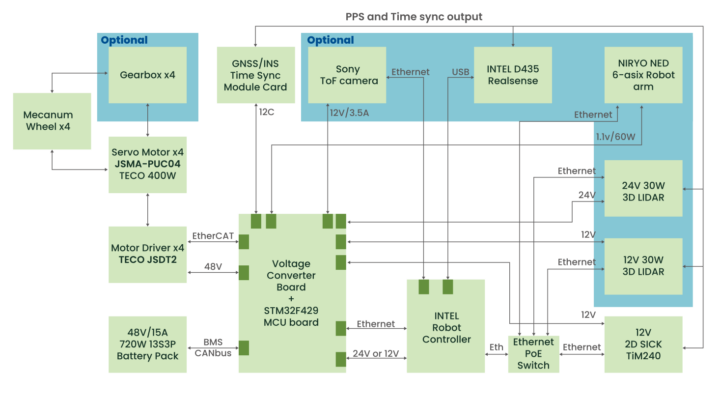

Syncbotic Syncbot is a four-wheel autonomous mobile robot (AMR) platform for research and education that can be fitted with an NVIDIA Xavier NX or an Intel Apollo Lake/Tiger Lake-based controller running Ubuntu 20.04 operating system with ROS 2 framework, and comes with an motion control MCU board with an EtherCat master and running Zephyr OS.

The robot comes with four 400W TECO servo motors, can handle up to 80kg payloads for sensors and a robotic arm, features 12V and 24V power output for sensors, four USB 3.0 ports, and can also be equipped with an eight-camera kit with Intel RealSense and ToF cameras.

Syncbot AMR specifications:

- Robot Controller Platform (one or the other)

- SyncBotic A100 evaluation ki (Apollo Lake E3940)

- SyncBotic SBC-T800 series (Intel Tiger Lake UP3)

- SyncBotic SBC W series (Intel Tiger Lake UP3, waterproof version)

- SyncBotic NSync-200 series (NVIDIA NX)

- Dimensions – 200 x 190 mm

- STM32-based Motion control board

- Networking

- 1x 10/100M port for EtherCAT master for servo motor control

- 1x 10/100M port for other propose

- CAN bus interfaces

- 1x CAN bus for Battery BMS (4-pin M12 A-coded)

- 1x CAN bus for other propose

- DI/DO interfaces – 24V DI/DO for status control, monitor

- I/O interfaces – 2x I2C, 5x PWM GPIO, 2x SPI, 2x UART on terminal block, 1x micro USB port

- Debugging/programming – 1x USB JTAG interface

- Power Output – Integrated 48V 600W power module and support 4x stable 48V output with 15A fuse for servo motor (upgradeable to 1200W power budget)

- Power Input – Up to 48V/15A

- Networking

- Servo Motor / Motor driver / Gearbox

- Motor Driver – 4x TECO motor driver

- Servo Motor – 4x TECO 48V / 400W servo motor, 3000RPM

- Optional Gearbox – 4x LIMING gearbox, ratio: 15, 2-stage with input flange

- Motor DI/DO – 6x 24V DI, 4x 24V DO, 1x DICOM, 1x DOCOM

- Host interface – 4x USB, EtherCAT IN/OUT

- Power Input – 48V DC, 8A continue, 11A for inrush

- Robot Sensors

- 2D LIDAR – 1x SICK TiM240 SLAM LiDAR on front side

- Optional 3D LiDAR – 1x Voledyne VLP-16 or Ouster OS0-32 3D LiDAR

- Optional SyncBotic TSMC card – 1x TSMC card with 9-axis IMU + L1 GPS

- Optional camera

- Intel Realsense D435i, D405

- oToBrite ToF camera, oToCAM500

- Optional Robot Arm – NIRYO Ned education robot arm

- Max payload – 80 kg

- Speed – 0.6m/s to 1m/s (2.1 to 3.6km/h)

- I/Os

- 3x Gigabit Ethernet with M12 connectors

- 4x USB 3.0 Gen1 Type-A connectors

- Misc

- Power button with LED

- Emergency button

- Blue LEDs for Robot controller and servo motor readiness,

- Red LED for servo motor alarm

- Battery

- Nominal voltage: 48V DC; range: 39V to 54.6V, 13S3P LG21700 Li-ion cell

- Power Input / output connector – Anderson XT60

BMS port 1x CANbus with M12 A-coded, 4-pin

- Power Output

- 2x 11.1V / 6A with circle connectors

- 1x 12V / 2A with circle connector

- 1x 24V / 2A with circle connector

- All power output support OVP, OCP, Short circuit protection

- Robot Dimension and Weight

- Wheel – 4x 5-inch mecanum wheels

- AMR Length – 600 mm

- AMR Width – 400 mm

- AMR Height – 200 mm

AMR Clearance – 20 mm - Weight – 20kg

That’s about all the information we have about the SyncBot robot itself, but you may find a few more details on the company’s website. The educational robot was brought to my attention through AAEON RBX-I2000 robot controller announcement, which Syncbotic sells as the SBC-T800 series. The new controller is powered by an Intel Tiger Lake UP3 Core i7/i5/i3/Celeron processor and features hardware-based time synchronization to improve sensor fusion on two connectors, with latency slashed from 100 to 200 uS by software to just 20ns.

The RBX-I2000 robot controller also comes with 4-channel sync ports, each supporting two channels of 9600bps and 115200bps, which combined with the built-in Xsens MTi-670 9-axis IMU and the Movella Xsens RTK, enable centimeter-level positional data. It runs Windows 10 IoT Enterprise by default, but Linux is available upon request. More details may be found on the product page.

Besides being used in the SyncBot autonomous mobile robot for education and research, AAEON expects the RBX-I2000 to find its way into smart agriculture and mining applications. There’s no public pricing information for the robot or controller. But the latter should cost over one thousand dollars and a fully equipped robot well over $10,000 considering the NIRYO Ned robotic arm above goes for about 2,900 Euros alone.

Jean-Luc started CNX Software in 2010 as a part-time endeavor, before quitting his job as a software engineering manager, and starting to write daily news, and reviews full time later in 2011.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress

It runs windows ? Why on earth would it need a desktop based os ?

“Windows 10 IoT Enterprise” is not a desktop-based OS, it’s for embedded and the internet of things. I think it’s what used to be called Windows Embedded and WinCE before that.

There are 2 Windows IOT Operating Systems – Enterprise and Core. Core is what I would have expected on this but it has enterprise installed by default which supports the whole Windows eco system. Maybe this is the right choice between windows flavours, but really I would expect Linux to be a test/dev environment, with bare metal used in production mode. As there are multiple cores, I would expect not to need a scheduler/kernel. Overview of Windows 10 IoT – Windows IoT | Microsoft Docs Major diff between core and Enterprise… “By contrast, Windows 10 IoT Enterprise is a full… Read more »