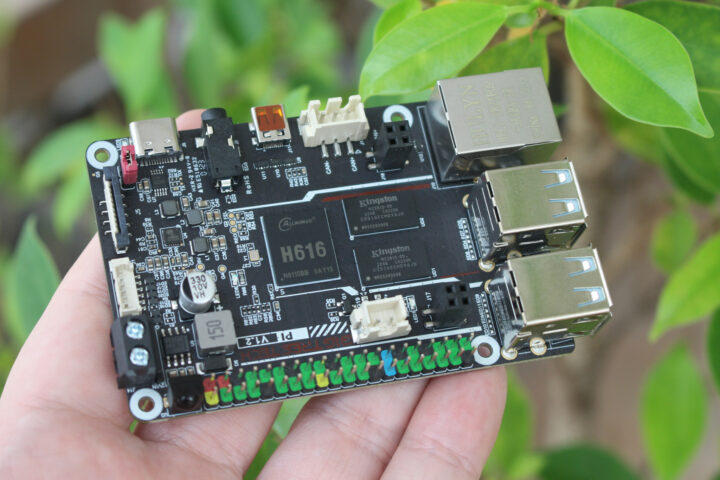

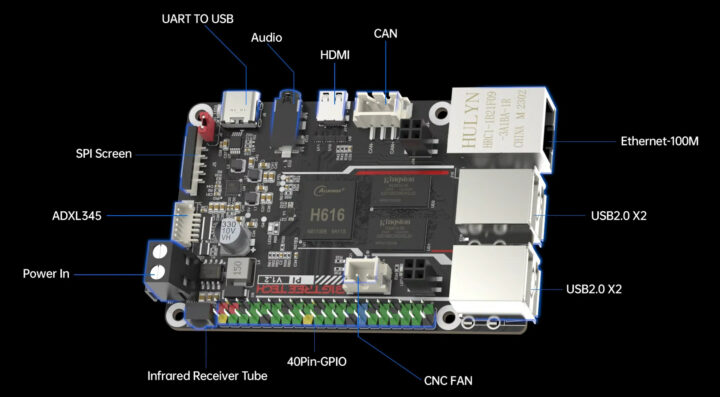

BIGTREETECH Pi v1.2, also known as the BBT Pi v1.2, is a Raspberry Pi-sized Allwinner H616 single board computer (SBC) specially designed for 3D printers with many of the same ports as the Raspberry Pi 3/4, but also features 12V-24V DC power input and connectors for the ADXL345 3-axis accelerometer, CAN Bus, and so on.

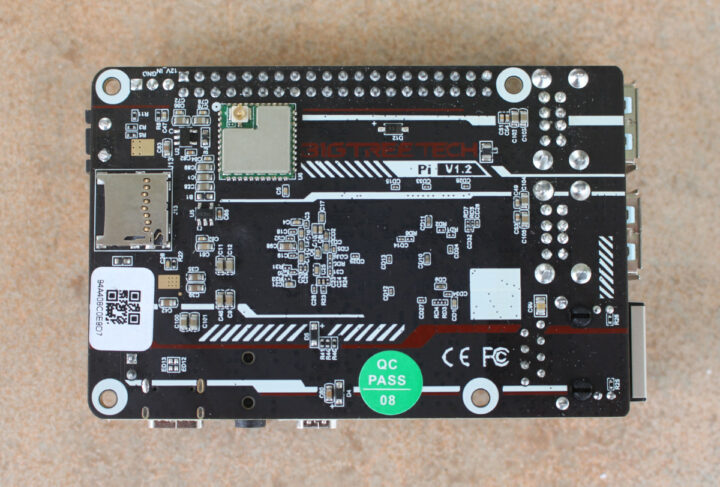

The board is equipped with 1GB RAM, a microSD card slot to run the operating system (Debian 11 with Klipper), a 4K capable micro HDMI port, Fast Ethernet and WiFi 4 networking, four USB ports, and the usual 40-pin Raspberry Pi header.

BTT Pi specifications:

- SoC – Allwinner H616 quad-core Arm Cortex-A53 @ 1.5GHz with Arm Mali G31 MP2 with support for OpenGL ES 3.2

- System Memory – 1GB DDR3L SDRAM

- Storage – MicroSD card slot

- Video Output

- Micro HDMI 2.0a port up to 4Kp60 resolution

- SPI port for display

- Audio – 3.5mm audio jack

- Networking – 10/100 Mbps Ethernet and 2.4 GHz WiFi 4 module with external antenna

- USB – 4x USB 2.0 Ports, 1x USB Type-C for power and UART console

- Serial – 3-pin CAN Bus connector for the U2C expansion module

- Expansion

- 40-pin GPIO

- ADXL345 3-axis accelerometer connector (SPI)

- Misc – Built-in IR receiver, 5V CNC fan header

- Power Supply

- 5V DC via USB Type-C port

- 12V to 24V DC via 2-pin terminal block

- Dimensions – 85 x 56 mm (3x mounting holes are in the same location as the Raspberry Pi)

The board is software-compatible with the BIGTREETECH CB1 system-on-module and BTT Pi runs the CB1 image based on Debian 11, Linux 5.16, and Klipper open-source 3D printer software. You’ll find the latest version of the OS image on GitHub.

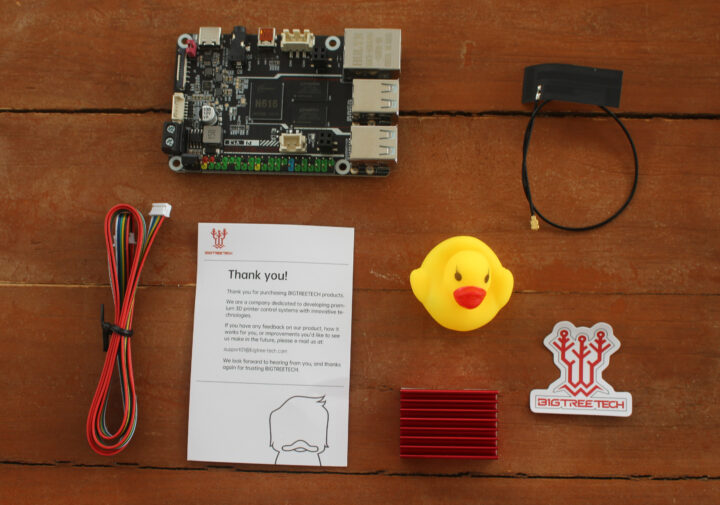

BIGTREETECH sent me a sample of the BTT Pi SBC, let’s have a quick look at the content of the package.

The board ships with the wireless antenna, some wires for the ADXL345 3-axis accelerometer module (not included), a Thank you note, a plastic duck, a red heatsink that will cover the Allwinner processor and RAM chips, and a sticker.

While the BIGTREETECH Pi v1.2 does have the same size as the Raspberry Pi 4 Model B and the USB and Ethernet ports are arranged in the same way, the comparison stops there, and the BBT Pi v1.2 board won’t fit in most Raspberry Pi enclosures. You should still be able to mount it on a chassis with holes reserved for the Raspberry Pi 4, but only three holes are aligned the same way which should probably be enough for most installations.

BIGTREETECH Pi V1.2 board is sold on Aliexpress for $33.68 including shipping, on Amazon ($45.99), as well as on biqu.equipment. I’ll probably review the board as an SBC as the company also sent the software-compatible Pad 7 with a 7-inch touchscreen display and the BIGTREETECH CB1 system-on-module, which I’ll cover later today or tomorrow, and review with the Creality Ender-3 S1 Pro 3D printer or another 3D printer.

Jean-Luc started CNX Software in 2010 as a part-time endeavor, before quitting his job as a software engineering manager, and starting to write daily news, and reviews full time later in 2011.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress. We also use affiliate links in articles to earn commissions if you make a purchase after clicking on those links.

A 10/100 Ethernet, when the SoC itself supports gigabit as well? They’re saving something like 30 cents in components, if even that! I’m also not aware of any company selling a 100Mbps WiFi-chipset, so either Biqu is exaggerating the performance of a 72Mbps-one or they’re using a higher-speed chipset, but its performance is limited in some way.

It looks like the chip has a 10/100 PHY built in as well as just a 1000G MAC. So, for GigE (which isn’t needed in this application), you’d need an external PHY and that board looks pretty packed. They could have made the board more dense by using smaller packages for the components, but they seem to have chosen cost and availability in their design.

1G MAC. Imagine a 1000G MAC in a cheap SOC….

As much as it’s not impressive in terms of specs, this board is built-for-purpose and I think they nailed it. It’s got the features you’d want in an SBC meant to run Klipper for a 3D printer. Plenty of CPU for the job, all the right I/O, right form factor (keep in mind, this is for people with 3D printers, needing a non-standard case is just a 3D print away), and a great price.

If/when I get time to convert my two workhorse printers to Klipper, something like this would be really handy–but I’m already set for hardware with a bunch of de-chromed chromeboxes.

If you look at it without the 3d printing ‘lens’, then this may not look like a very appealing board, but I’m stuck with that set of expectations, so it looks good to me.

There’s that sweet free prime shipping…only $12.

I guess it’s $6 for the free shipping and $6 for the convenience of getting it in “2 days”…I loathe Amazon.

Nevermind the $10+ you pay monthly.

As far as the device goes, it’s not bad but I think it’s a tad overpriced.

Does H616 even has that OpenRISC core available for printer control?

I’m not sure, but the H616 board does not control the printer directly, it still needs to be connected to a control board.

To elaborate on what Jean-Luc said, Klipper is a two part system. All of the gcode parsing and motion planning takes place on a ‘PC’ (be it a raspberry pi, actual x86 PC, or some other type of general purpose machine running Linux) and a low level controller board like RAMPS, etc. The latter just controls the machine and handles the real time work.

It works so well because all of the work that could benefit from more computation is moved to the PC while the micro is freed to do real time work which it’s best at. This more appropriate division of labor leads to a more performant system.

Since existing printers already have a low level controller in them, this board is meant as an enhancement to an existing system. Thus the existance of the low level controller is assumed.

There are systems based on BeagleBone like boards where there is a real time controller built into the SoC that runs the high level Klipper code, but those are the exception, not the rule.

No, the H616 does NOT have that OpenRISC core anymore. With the SoC targeting set top boxes, they saved even on that free IP, and a simple state machine logic now covers the tricky CPU power-off sequence.

I would be curious to know if anyone has ever used an RTOS on an ARISC in the other Allwinner cores, in a BeagleBone PRU like fashion, to control GPIOs under realtime conditions.

https://github.com/Klipper3d/klipper/tree/master/src/ar100

My question is why wifi 4. What is that, wifi n? With wifi 6 here and WiFi 5 (ac) commonplace this really kneecaps it moving forward. Id much prefer they manufacture boards with the most recent standard available so it has more total lifetime before becoming e waste

This really sucks because having a dedicated pi for 3d printing makes a lot of sense. Having on board power regulator that does 24v or even 48v would be fantastic. The wifi really kills it for me

Using 802.11n helps keep the price low. All versions of WiFi are backward compatible, so it’s not like WiFi will stop to work in a couple of years because of a lack of compatibility with a new router.

> All versions of WiFi are backward compatible

Not all since 6GHz Wi-Fi is a clear cut (though APs today usually support 2.4/5GHz as well). Wi-Fi backward compatibility introduced potential performance, connectivity and security issues each time a new generation of the specs had been defined. With ‘legacy clients’ often you can’t enable all features of a new AP and there might be situations when you want to operate more than one AP with very old wireless clients.

Serious question, how much bandwidth does a 3D printer need?

Why limiting the question of Wi-Fi standard to bandwidth/performance? Performance-wise legacy clients consume (way too much) airtime and their existence may affect performance of other wireless clients as well.

And there’s more to it. Old chipsets are still affected by BroadPwn/KR00K, there are connection issues with modern AP, WPA3 vs. WPA2/WPA/WEP and so on…

Does anyone have a good source for a mini pcie half size card that is well compatible and supports at least ax?

Intel? They make the 7260 which should do what you need.

It’s less about bandwidth and more about stability. My printers running pi 3s will frequently drop webcam streaming but otherwise work fine. The one with a pi4 never has this issue and responds better, never disconnects from wifi. Even if this board supported the lowest tier of wifi AC, that would be a boon – running in wireless ac only rather than a/b/g/n/ac gives a better quality connection with less issues and less overhead.

The real connection is why not have at least wifi 5/ac. Even if it bumps the wireless module from $5 to $10 imo worth it for making something have a significantly greater lifetime before becoming e waste.

Because the Pi3 has crap Wifi ability? Want better WiFi? Put in a USB wifi stick or something. FFS, this is a $34 board.

Not much and the people here complaining seem to not be the intended users of this board. For the use intended, this board has very sufficient networking. If you have unreliable connections using WiFi4, then it’s likely your client that’s not working, not WiFi4 as a system.

Could the BTT TFT70 v3 be connected and run smoothly with this board? I have a new one and want to use it with klipper. Currently it’s running well with reprap firmware without SBC

You’d probably want to see if Klipper supports it. As far as a connection, you can either connect it to the printer controller board (whatever you’re using) or to this board. It looks like all it takes is a serial connection.

I just reread this after the review of the tablet with klipper. The comment about the board being the same shape as the RPi, but different enough that cases for the Rpi won’t fit. My first response is *oh, no! Whatever will me and my 3D printer do about not having a standard case to use?* Oh, right, I’ll just print one. 🙂 Things that used to be problems really aren’t once you have a 3D printer.

Hi, have you got the right configuration and rpi pin for using the BigTreeTech ADXL345 via SPI? Igot the following configuration but it doesn’t works:

adxl345]

cs_pin: rpi:none

spi_bus: spidev1.1

[resonance_tester]

accel_chip: adxl345

probe_points:

100, 100, 20

That’s what I use in the Pad 7: https://www.cnx-software.com/2023/05/29/review-of-bigtreetech-pad-7-klipper-pad-with-creality-ender-3-pro-s1-3d-printer/

[mcu CB1]

serial: /tmp/klipper_host_mcu

[adxl345]

cs_pin: CB1:None

spi_bus: spidev1.1

axes_map: x,y,z # Modify according to the actual orientation of the ADXL345

installed on the printer.

[resonance_tester]

accel_chip: adxl345

probe_points:

# Somewhere slightly above the middle of your print bed

117.5, 117.5, 20