STMicro has announced the ultra-low-power STM32U0 Arm Cortex-M0+ microcontroller family running up to 56 MHz that reduces energy consumption by up to 50% compared to previous product generations such as STM32C0 or STM32L0 while targetting SESIP Level 3, PSA-Certified Level 1, and NIST certifications. Separately, the company also introduced a new 18nm FD-SOI manufacturing process for STM32 microcontrollers that will replace the 40nm process currently used.

STMicro STM32U0 Cortex-M0+ MCU

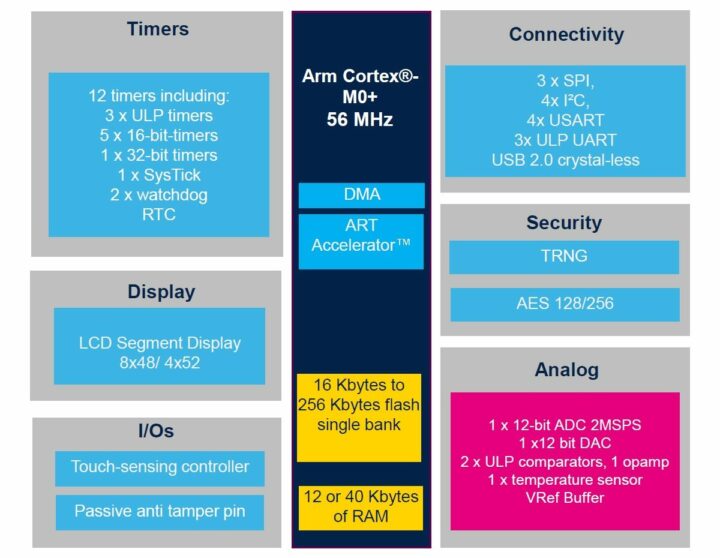

STMicro STM32U0 key features and specifications:

- MCU Core – Cortex-M0+ up to 54 MHz with ART accelerator

- Memory / Storage

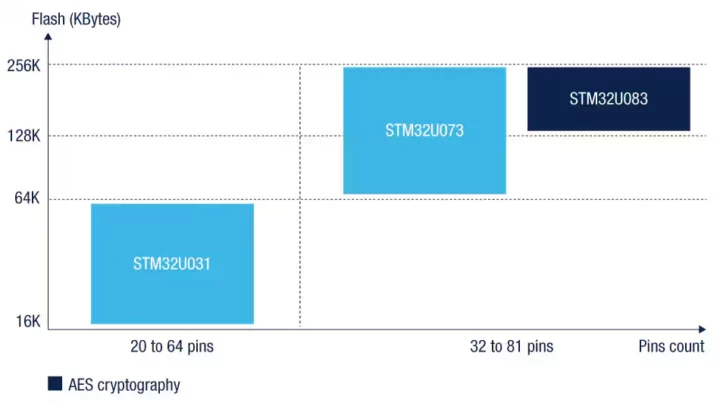

- STM32U031x – 12KB SRAM, 16 to 64KB flash

- STM32U073x – 40 KB SRAM, 16 to 256 KB flash

- STM32U083x – 40 KB SRAM, 256 KB flash

- Display – LCD controller for 8×48 or 4×52 segment displays (STM32U073, STM32U083)

- Peripherals

- 3x I2C, 2x SPI, 4x USART, 2x low-power UART.

- Up to 21x capacitive sensing channels

- USB – 1x USB 2.0 device interface (STM32U073, STM32U083)

- Analog – 12-bit ADC, up to 2x embedded rail-to-rail analog comparators, one operational amplifier

- Timer – General-purpose 32-bit timer, 16-bit PWM timer dedicated to motor control, 3x general-purpose 16-bit timers, and 2x to 3x 16-bit low-power timers

- Low-power RTC

- AES hardware accelerator (STM32U083 devices)

- Power Supply – 1.71 V to 3.6 V power supply

- Power Consumption (from STM32U031 datasheet)

- VBAT mode: 130 nA (with RTC and 9 x 32-bit backup registers)

- Shutdown mode (4x wake-up pins): 16 nA

- Standby mode (4x wake-up pins): 160 nA with RTC, 30 nA without RTC

- Stop 2 mode: 630 nA with RTC, 515 nA without RTC

- Run mode (LDO mode): 52 μA/MHz

- 4 μs wake-up from Stop mode

- Packages

- STM32U031 – 20 to 64 pins, in TSSOP, WLCSP, UFQFPN, LQFP, and UFBGA.

- STM32U073 and STM32U083 – 32 to 81 pins, in UFQFPN, WLCSP, LQFP, and UFBGA.

- Tempetature Range – -40°C to 85/125°C

- Process – 40nm

STMicro explains the STM32U0 has “extremely low static power consumption in standby mode and superior wake-up performance, enabling the MCU to spend more time in power-saving sleep modes to minimize average energy demand”. One of their early-access customers used the STM32U0 in security cameras to wake the device when motion is detected, and others integrated the new Cortex-M0+ MCU into long-lasting smoke detectors and a water meter.

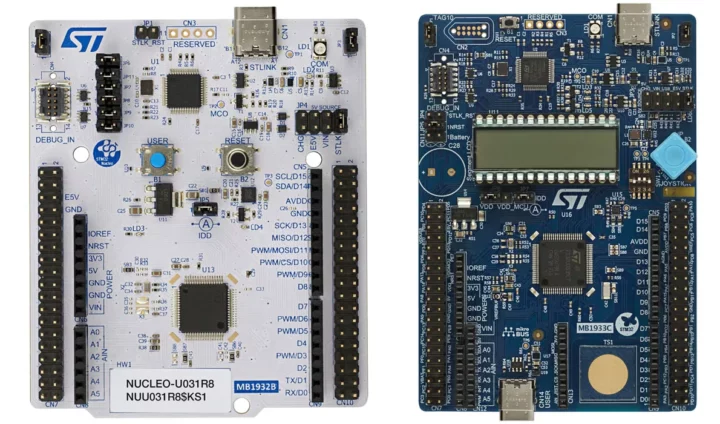

STMicro provides three development platforms for the new STM32U microcontroller, namely the NUCLEO-U083RC Nucleo board, NUCLEO-U031R8 Nucleo board, and STM32U083C-DK Discovery kit. All can be programmed with the usual development tools from STMicro.

Typical applications include industrial devices (thermostats, smoke detectors, heat cost allocators, door locks), medical equipment (insulin pumps, glucose meters), smart meters (water, gas, electricity), and consumer devices such as activity trackers, GPS logger, and headphones.

The STM32U0 series is in production now and pricing starts at $0.68 for 1,000 units. Evaluation boards can be purchased today for $10.31 for the Nucleo boards and $20 for the STM32U083C-DK Discovery kit. You’ll find more details including documentation and purchase links on the product page.

18nm FD-SOI process for STM32 microcontrollers

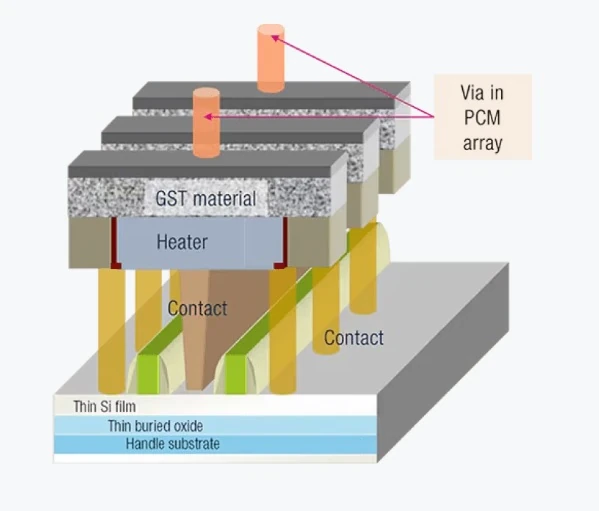

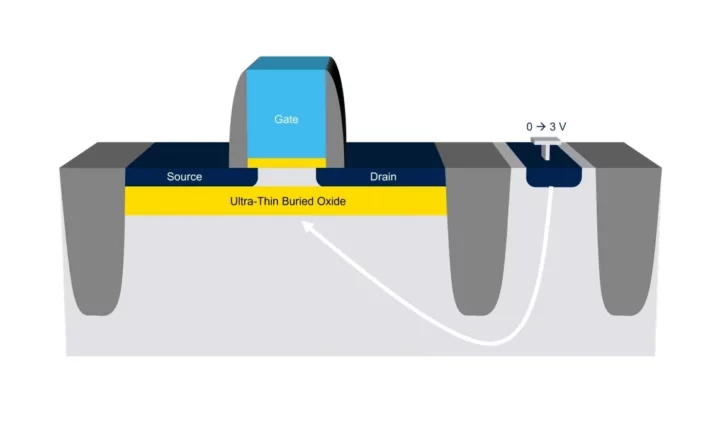

STMicro also announced its move to 18nm Fully Depleted Silicon On Insulator (FD-SOI) technology with embedded phase change memory (ePCM) for the next generation of its STM32 microcontrollers (MCUs). Compared to STMicro’s 40nm embedded non-volatile memory (eNVM) technology used today, 18nm FD-SOI with ePCM delivers:

- More than 50% better performance-to-power ratio

- 2.5x higher non-volatile memory (NVM) density enabling larger on-chip memories

- 3x higher digital density for integration of digital peripherals such as AI and graphics accelerators as well as security and safety features

- 3dB improvement in noise figure for enhanced RF performance in wireless MCUs

STMicro states the technology is capable of 3V operation to supply analog features such as power management, reset systems, clock sources, and digital/analog converters, and further claims it is the only sub-20 nm technology supporting this capability.

The first STM32 Cortex-M MCU based on the new 18nm technology will start sampling to selected customers in H2 2024, with production planned for H2 2025. Additional information may be found in the press release.

Jean-Luc started CNX Software in 2010 as a part-time endeavor, before quitting his job as a software engineering manager, and starting to write daily news, and reviews full time later in 2011.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress. We also use affiliate links in articles to earn commissions if you make a purchase after clicking on those links.

52µA/MHz means 2.6mA at 50 MHz. That reminds me the burning hot 486DX40 that we were overclocking to 50 MHz back then, you could almost cook an egg on them. 2.6mA is just a faint LED. Nice progress over time, which also shows that sometimes it can be worth replacing old hardware 😉

My dx2 66 was quite tame, without a fan, also the P100 was harmless, i even put aluminium film between the heatsink and the cpu until i found the reason for the gap…

But very impressive what a uP nowadays can do

Spoilers from datasheet:<10mA at full load with everything on, it seems like my prayers for ULP “I/O expansion” microcontroller has been answered.

I thought that flash/non-volatile memory did not scale at all below 40nm and it was the main reason why microcontrollers did not shrink past this barrier. Since most of the die space is already occupied by flash memory at 40nm, did they just sacrifice cost in order to lower power requirements?

Nope, the article says they’re using embedded phase change memory instead. It’s still less of a shrink than the digital parts, but 40% the size vs 33% isn’t too bad.