COVID-19 has disrupted most people lives well beyond the health crisis, with an economic fallout on-going that may lead to a 24% GDP contraction in the US and up to 12% worldwide in Q2 2020, and I assume the consequences may span over several years, so we should do everything to mitigate any effects from the disease.

Right now, the urgent part is to handle the health crisis, and there’s a shortage – or soon will be – of medical supplies such as ventilators for people in critical conditions, and if hospitals become full they’ll start refusing admissions of some people even in critical conditions, as it happened in Wuhan, letting people die at home.

So there are various initiatives and projects to develop open-source ventilators. First, Innovation Management reports Ennomotive has launched a non-profit online competition for the ideation of low-cost, easy-to-build solutions with the goal of speeding up the availability of ventilators in hospitals everywhere to help patients with coronavirus.

The second project is more practical, as instructions to build an Arduino-based open-source ventilator or PAPR (Personal Protective Equipment) are provided on Github.

Big Fat Warning: there are significant risks in using this ventilator without medical supervision, and you may end up damaging the lungs of the person you may be trying to help if you don’t know what you are doing.

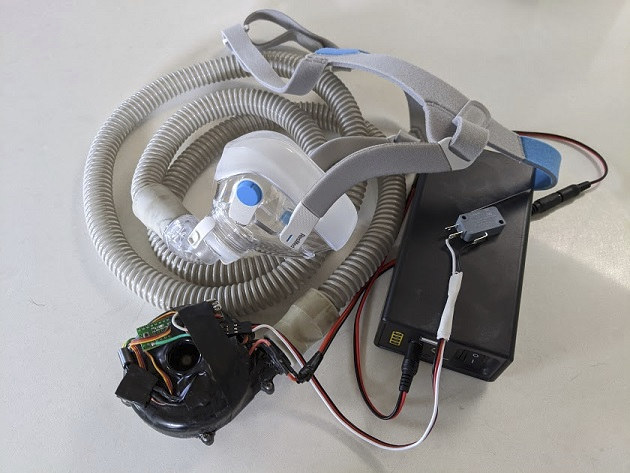

That’s why the developer recommends following the instructions to make an air-purifying PAPR as it’s much safer to use and may help caretakers avoiding infection. Here are the components used in the design:

- Continuous Positive Airway Pressure (CPAP) device available on eBay and Alibaba for as low as $20 in volume. The blower is usually a simple BLDC motor that can be driven with an Electronics Speed Controller (ESC) used by quadrotors and RC cars.

- Arduino Nano or compatible clone to control the motor speed, breathing cycles, and handle user input.

- Brushless DC Motor Electronic Speed Controller capable of at least 10A.

Button or switch for input control. The code cycles through 5 levels of pressure, and double click to switch between CPAP and BiPAP/Fixed PEEP mode. Such as this one. - 12V/5A+ DC power supply

- Tubing and face mask. A full CPAP face mask covers both the mouth and nose and enables pressure buildup in the lungs. They can be found on eBay or other places.

- Optional 12V battery backup.

The Arduino sketch to control everything is pretty simple with 174 lines of code. There are also some optional 3D printed parts available [Update: not recommended see below]. People from Apnea board have take interest and there’s a long general discussion about the topic.

Stay safe and good luck!

[Update: Prusa explains why it may not be a good idea to print your own parts for respirators at this time, but they have printed many protective shields instead and donated 10,000 to the Czech Ministry of Health with more coming]

Via Open Electronics

Jean-Luc started CNX Software in 2010 as a part-time endeavor, before quitting his job as a software engineering manager, and starting to write daily news, and reviews full time later in 2011.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress

This seems more like a dangerous hack to me, which is not even intuitive to use. If it’s meant to be used by the patients they can easily panic. If it’s meant to be used by people supervising the patient, they could have added an extra button to separate faster/slower. Also when used in continuous stream, most users would not even need the arduino, button etc, just connecting the right number of batteries to a blower is enough and way simpler. Correction on a point though. COVID-19 is not causing an economic fallout, it’s making people sick and killing some… Read more »

About the second point, it’s quite tough as politicians need to balance the health risk and the economy, People don’t react to math that well, as shown by the government reaction to terrorist attacks which are statistically insignificant in most countries. The leading cause of death are cardiovascular diseases which kill 17 million people yearly. If we let COVID-19 run its course with 50% infections and 2% death rate that would be 78 million deaths that would be untenable politically. It’s quite possible COVID-19 death rate is overstated, as now people are comparing *confirmed* COVID-19 to *estimated* flu cases. But… Read more »

> Politicians who are seen as doing something are more likely to be re-elected as well That was exactly my point. They prefer to do what was proven to fail abroad or even to increase the side effects. Despite strong confinement, reported cases still increase exponentially in Italy, and I’ve been convinced from day 1 that in France we’ll go through this as well. Probably that forcing sick and non-sick to be confined together makes the problem worse, just like in this boat where the same mistake was made a few weeks ago, after which it was admitted that it… Read more »

Come on people. Most politicians are following, sometimes with great reluctance, what the scientists, doctors and epidemiologists are telling them to do to reduce the projected death rate if nothing is done. Are politicians rotten narcissists? Yes, some of them are. This does not imply they always make rotten decisions. If there was a poll asking each citizen: you can maintain you egotistical way of life BUT a large number of people (from 30M to 300M world-wide) will die. This includes: weak old people, younger people with co-morbidity, heavy smokers, unlucky people who drew bad entries from the genetic lottery.… Read more »

On the same theme

Oxford University and King’s College London are developing ventilators

Engineers, anaesthetists and surgeons from the University of Oxford and King’s College London are building and testing prototype ventilators that can be manufactured using techniques and tools available in well-equipped university and small and medium enterprise (SME) workshops.

https://www.electronicsweekly.com/news/archived/resources-archived/oxford-university-kings-college-london-developing-ventilators-2020-03/

Time for people and countries to use the internet and knowledge to work together, to benefit all.

The cnx-softwares above post is about open source. My following post is cheap emergency ventilator in times of crisis. I often do a internet search on a topic, as it can save reinventing the wheel when you have a problem. So i searched low cost ventilators. Then read quite a few articles my search returned. These suggested premium ventilators can cost upto $30,000 . But what I learnt most, is we hairless upright apes need to read history more ! xxxxxxx July 15, 2010 xxxxxxxx Students develop a low-cost portable ventilator by Massachusetts Institute of Technology Cost around $100 quoted… Read more »

One of the biggest problems for a project like this is that just about every design will be covered by some minor patent or other. So the device may be cheap to produce, but the legal battle that the producer or even the end-user can be threated with becomes the real issue.

Once upon a time patents provided a fair return on investment, now they are used as weapons that restrict markets rather than protect investors and if they can’t use patent law they will move onto trademark and copyright law.

Sadly a very true statement.

Why not simply use a veterinary ventilator?

Even the MIT, safety first.

– https://e-vent.mit.edu/

What about this one:

https://www.youtube.com/watch?v=p47dtsTrSBI

Now Rpi ” A team in Colombia is to test a ventilator made with a Raspberry Pi computer and easy-to-source parts. The design and computer code were posted online in March by a man in California, who had no prior experience at creating medical equipment. Marco Mascorro, a robotics engineer, said he built the ventilator because knew the machines were in high demand to treat Covid-19. His post prompted a flood of feedback from healthcare workers. He has used the advice to make improvements. “I am a true believer that technology can solve a lot of the problems we have… Read more »

List of 80 open source ventilators ranked by various factors including Openness, Buildability, Community Support, Functional Testing, Reliability Testing, COVID-19 Suitability, Clinician Friendly

https://docs.google.com/spreadsheets/d/1inYw5H4RiL0AC_J9vPWzJxXCdlkMLPBRdPgEVKF8DZw/edit#gid=0