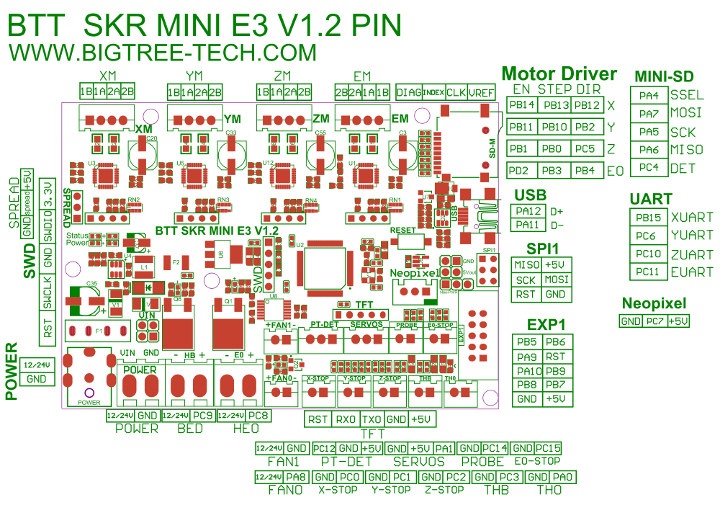

Karl here with a quick upgrade guide. The one complaint I had in the review of the SV01 3D printer was it was loud. Today we are going to look at resolving part of the problem by replacing the Creality board with the BigTreeTech SKR mini E3 V1.2 control board sold on Amazon for around $37. Fan noise at a later date. This board is ideal because the SD card, USB, and screws line up for nearly a perfect replacement. I did not bother hooking up the filament runout sensor. I have never found them particularly useful and always ensure I start with enough filament and bypassed it for the review. The board comes with TMC2209 drivers which significantly reduce the stepper motor noise as well as stop any salmon skin.

SKR Mini E3 Warning

This board is a replacement for the board found on the Ender 3. Below is from the manual. I purchased a clamp meter to test the bed for the SV01. The bed pulls 9.6 amps max or 230W and the Ender 3 bed is rated at 220W. After it reaches temp, it cycles 9.3 amps or 223 Watts on and off. The bed on the SV01 bulls about an extra .5 amp when initially heating up. 5% more…this may be within tolerance. I don’t think that this will be an issue. Do this upgrade at your own risk. I have had no problems. You have been warned. Note that an external MOSFET can resolve this issue completely. All power would route through the MOSFET and only use the Bigtreetech SKR Mini board for control.

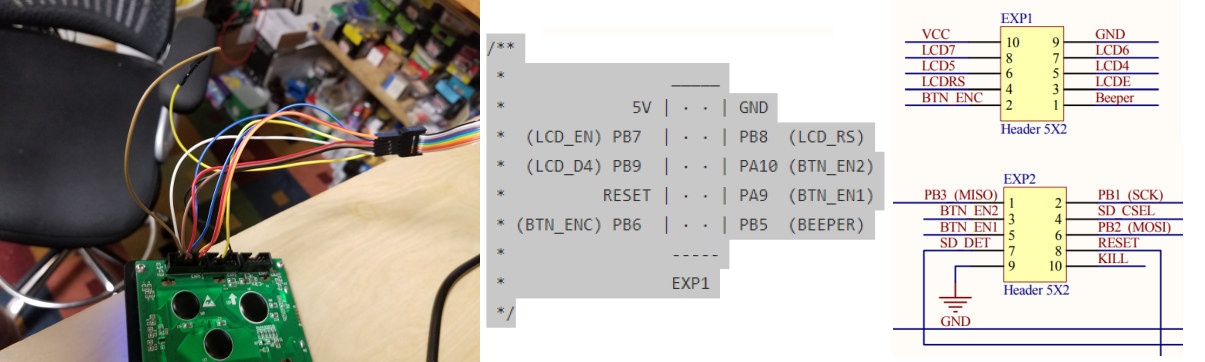

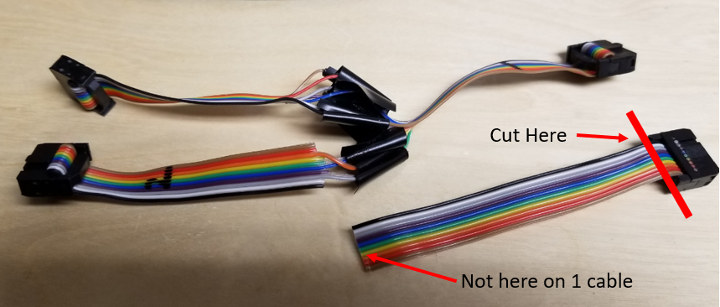

Wiring

One modification had to be done to wiring. There is only 1 Z output so you must splice the 2 connections down to 1 in parallel.

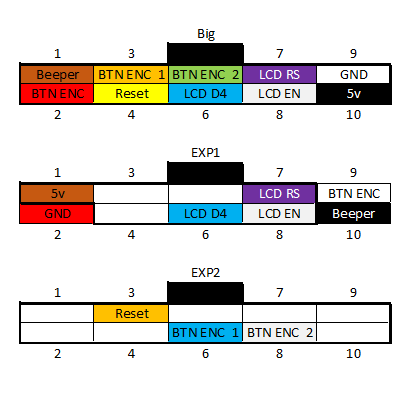

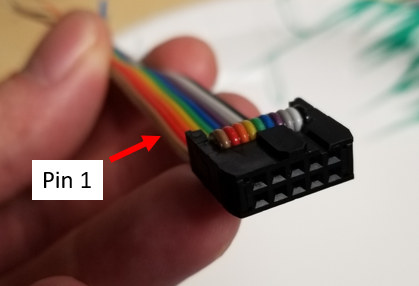

All the below connect is not necessary. The screen has an exp3 connection on it with the correct pinout for the SKR mini E3. Take the connection from the E3 on the screen to the 10 pin connector on the board. No splicing necessary.

Connections

All the rest of the connections just plug in. I didn’t even bother tracing the thermistors or fans and plugged them in. I started heating the hotend and if the wrong temp rises, swap. If the fans are backward just swap. I didn’t connect the fan that keeps the board itself cool and just left the plate that covers the bottom of the printer off for easy access. You can directly connect this fan to the power supply if needed.

Marlin

I used Marlin from Bigtreetech’s GitHub page and forked it here. You can download directly from my fork. If you are OK without a filament runout sensor, download the firmware.bin and place it on the SD card and boot up the printer. It will load the firmware that is on the SD card. There are many guides to compile and flash the firmware and won’t go in-depth here. I would imagine the maintainers of Marlin will take these changes for the board soon if they haven’t already.

Conclusion

I am very pleased with the upgrade to SKR Mini E3 board. Now the only thing that is too loud is the fan on the power supply. Fan noise doesn’t bother me as much as noisy steppers so I may leave it. I think it is because it is a constant sound versus one that goes up and down.

Karl is a technology enthusiast that contributes reviews of TV boxes, 3D printers, and other gadgets for makers.

Support CNX Software! Donate via cryptocurrencies, become a Patron on Patreon, or purchase goods on Amazon or Aliexpress

That’s a pretty good price for a board with four 2209’s on it! How did it perform? I’ve been upgrading a number of printers to 2208’s and it’s been a great improvement.

I also installed two 2209 in my laser engraver and it changed everything! No more leftover traces on PCBs from areas that were not accessible with the original steppers, and the silence is much appreciated, I’ve completely forgot about the noise the previous ones were making 🙂 Also I suspect that they better handle accelerations because on a few occasions in the past I got a few bad moves on multi-pass cutting of large figures requiring lots of traveling, indicating missed steps. It has never happened since the upgrade.

The price is another factor that makes this board attractive. It prints very well. The printer already did great.

If you really dont want to mess with any wiring you can use one of these for the stepper motors. Contributed from the Sovol FB group. https://www.aliexpress.com/item/32870988156.html

While reading the article, I was thinking that I would have chosen to make an adapter instead of alter the motor wiring. I like to leave myself the ability to back out of any changes. Maybe from too many years as a sys-admin?

I made a silly mistake. The whole splicing thing is unnecessary. Just connect the exp on the board to the exp3 on the screen. The more you know!

I have done some more tweaking and github is updated to reflect. All the advanced features are turned on now. It really does print amazing. Linear advance with a setting of .2 for my machine. If you think I should turn on permanently let me know.

Is it possible to use the BLTouch sensor with your firmware ?

Just need to turn it on and compile. Should be no problem

So today i got to install the BLtouch and i tried to change your firmware to enable it in marlin but when i load the compiled firmware on the sd card my sovol didn’t wanted to boot. Have you tried the skr mini e3 in the meantime with the bltouch ?

I haven’t tried with bltouch. Have you tried compiling with no modifications? This can tell us if your setup correctly. (Or maybe my GitHub is messed up) I just got my replacement board. Mine fried. FYI this board is now supported in mainline Marlin so you don’t have to use this repo any more. When I install next week. I’ll create a config for mainline and share in this repo. If not already done I’ll submit the config to be added to mainline.

I think it is because i used PlatformIO 4.10 and there was a problem with the version you used. It would be awesome if you could create a repo i would try it with that.

You are right. I remember now that I had to downgrade something after this article was wrote. You can take the configuration.h and configuration_adv.h and and dif them with stock marlin 2.0 if you don’t want to wait for me to do it. Or just take the bin file and run without bltouch for now.

Github is updated with new Configuration.h and Configuration_adv.h compatible with latest Marlin 2.0.1

Nice article.

While the modifikation of display cable is not necessary, I like the information as I intend to change to a skr touchscreen with 12864 emulation. It does not have the special Ender3 connector, so the description is very helpful.

One point for z:

As far as I know, two stepper motors should not be put in parallel if it can be avoided, but in serial. While on 12v there is nothing else than parallel possible (so parallel connecting is very common) in 24V you can connect the steppers in serial.

I now upgraded the Sovol to an SKR e3 mini (v1.0) myself. It works quite well – and silent. I connected both z-motors in serial, works perfect. For even less noise, I use https://www.thingiverse.com/thing:4013256 with a step-down converter to 5V and a 4040 Noctua-fan for Coldend. Also a 5050 blower for part cooling (which has more airflow, so you can reduce noise by tuning it to 70% having same airflow as the original fan with 100%). So only the fans in the base are a bit loud, but that will be done next. I replaced the ultrabase-style hotbed by a… Read more »

Glad to hear your success….i am still impressed with the mostly stock printer. I am interested with the magnetic spring steel sheet….with the odd size bed do you have some hangover on the edges….if you have a link i would be interested.

Hi, Ole I have a question: How would you put t he z motors in serial?

I think we meant the same thing. No way to put in series.

Hi, use that one for serial: https://www.thingiverse.com/thing:2538913

Cool yes another option

Hi Karl, I tried to kompilier your Version with Arduino but got allways many failures. What setup for Arduino need to do? I found this one but don’t work together:

https://github.com/bigtreetech/BIGTREETECH-SKR-mini-E3/blob/master/firmware/V1.2/Marlin-2.0.x-SKR-Mini-E3-V1.2/config/examples/Malyan/M200/README.md

Does anyone know if the .bin file would work with the 2.0 version of the board?

How do I get the filament sensor to work with this firmware?